Adding Functionality

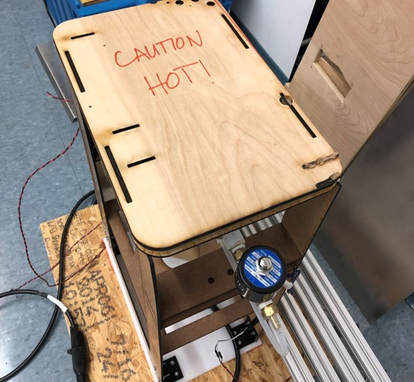

During sprint three we finished the proof of concepts for the rest of our subsystems and began the finalization of the whole system. We set out to create a MVP of the cup dispensing, filter dumping, and conveyor belt subsystems as well as addressing some safety concerns mentioned in our previous design reviews. We also reworked the code and electronics to be simpler and easier to understand as well as adding to the UI.

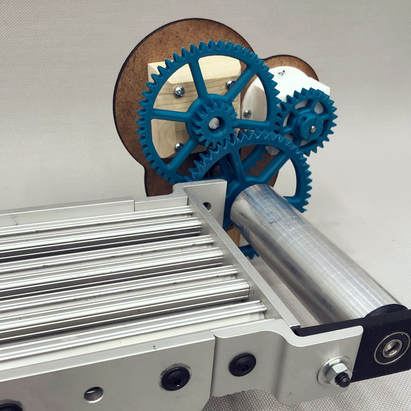

Conveyor BeltThe conveyor belt was also constructed this sprint. The body was built from scrap aluminum we found laying around. The rollers were lathed out of aluminum stock and are driven by a heavily geared down stepper motor. At first we purchased an industrial belt on the internet but found that it was far too stiff to be usable in our system. We instead repurposed an old curtain that was about to be thrown away and have found it to be very effective. (We also use the rest of the curtain as the background for our pictures).

|

Bean Grinding UpdateAfter lots of testing with the lever arm design we came to the conclusion that it was best to remove the lever arm altogether. Although the lever was working very consistently with a 22g test weight, when using actual grounds the weight distribution of each grind made the lever very inconsistent. In addition to this when the grounds would empty sometimes they would not all dump out. Due to the time constraints we had on this project we decided it simply was not worth the trouble. We instead decided to do a time based grind.

|

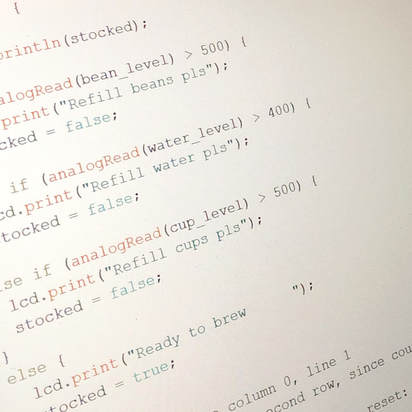

Code and Electrical OverhaulOur initial electrical layout consisted of one arduino uno communicating with many other “satellite” arduinos that would in turn control each subsystem. In order to simplify the system we purchased an arduino Mega that controls every system except for water heating. We felt water heating should remain on a seperate board as it is running off of AC power. The code was changed in order to fit this new structure

|

Filter DumpingInitially we wanted to work in a system for removing used filters and placing in a new one. We decide to only pursue the dumping aspect as separating coffee filters can be difficult even by hand sometimes. This sprint we designed and prototyped this system. It uses a rack and pinion in combination with a cloth hinge to move the filter forward until the cloth hinge can move freely, pivoting the filter cone 90 degrees and dumping the used filter into a trash bin.

|

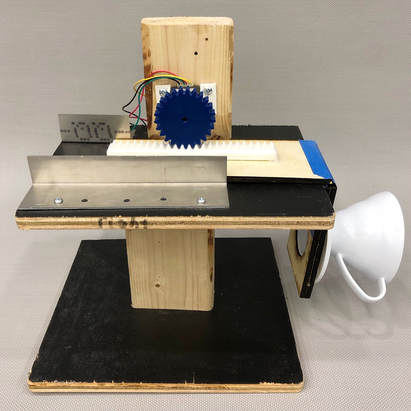

Cup DispensingThis sprint we also took up the task of designing and prototyping a cup dispensing system. We used a rack and pinion driven by a geared down stepper motor both for more torque as well as lower RPM in order to achieve the very small change in distance we needed to push out only one cup at a time. The cups are held in place by sheet metal arms that have just enough give to release a cup when the rack and pinion actuates.

|