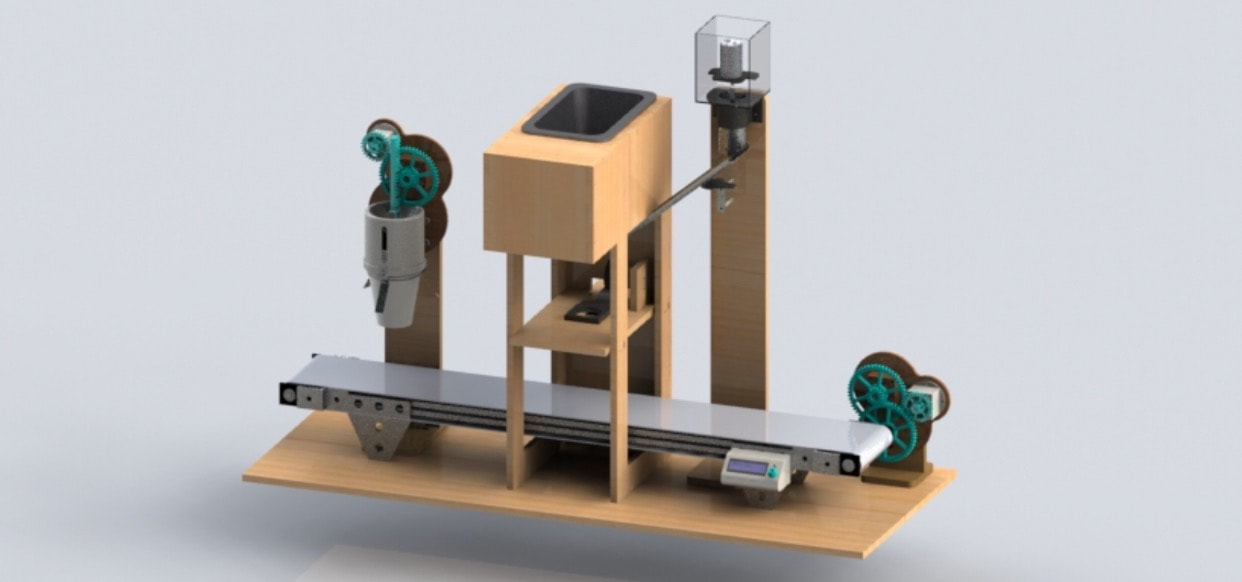

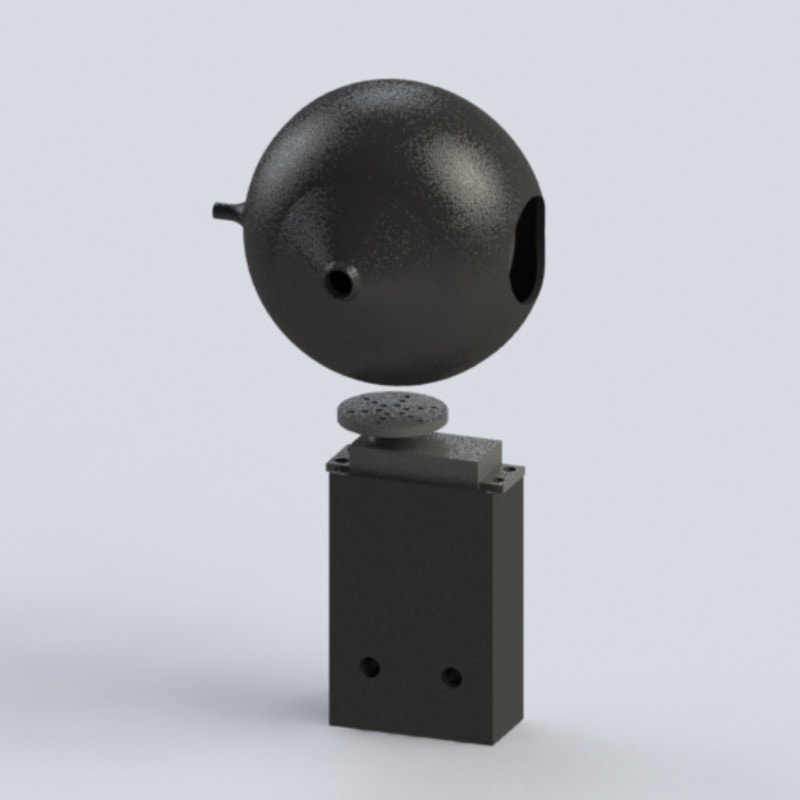

Final Rendering

Here you can see the mechaical design of BaristaBot come to life. The link below will take you to the GrabCad page where you can download the parts.

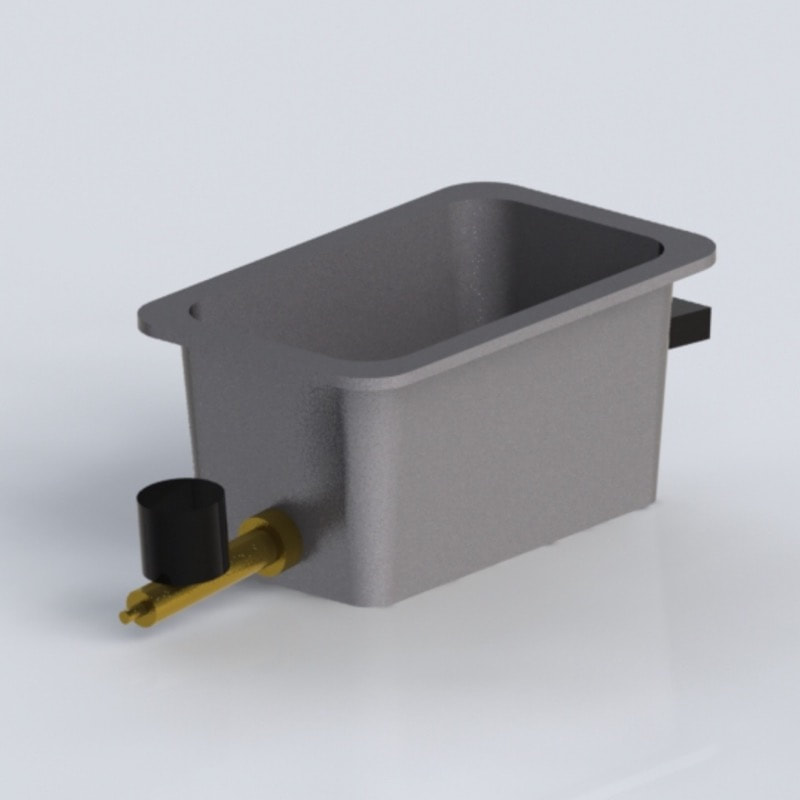

Pour TowerThe pour tower is where most of the coffee making process occurs. Water is heated in the top bucket, moves through the solenoid into the spiral pouring mechanism, then falls through the filter cone and into the cup waiting below. We iterated on the pour tower several times throughout this process, moving from having everything housed in the same tower to redesigning it to function with a seperate bean dispenser tower, a filter arm, and a conveyor belt.

|

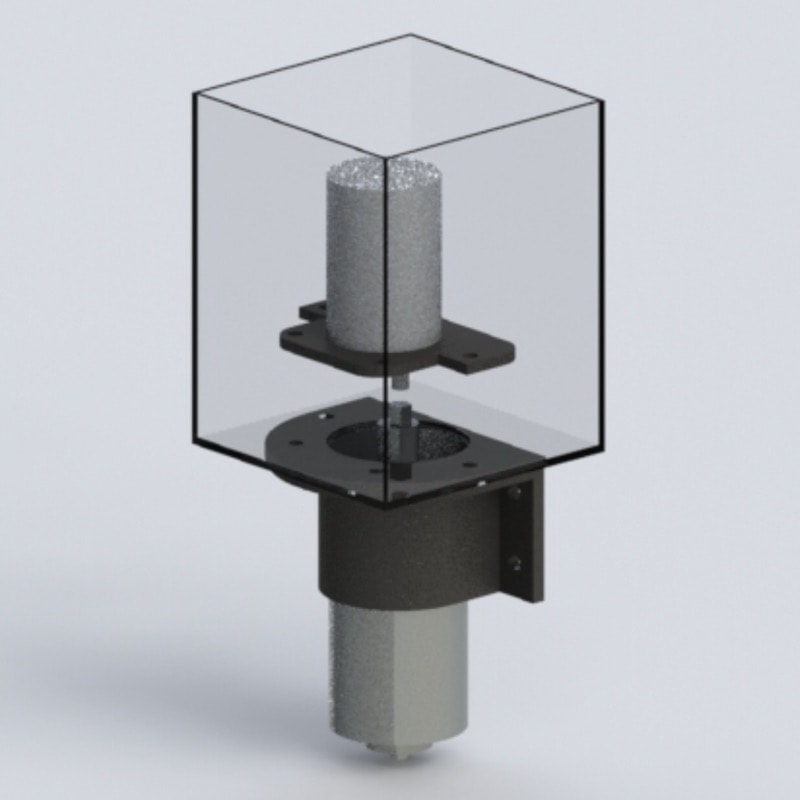

Water HeatingThis system is comprised of a stainless steel container with an AC-powered heating element on one end and a solenoid valve on the other. The solenoid valve is activated by an Arduino when it senses that the water has heated to the correct temperature, and water then pours through a flexible silicone tube connected to the spiral pour system.

|

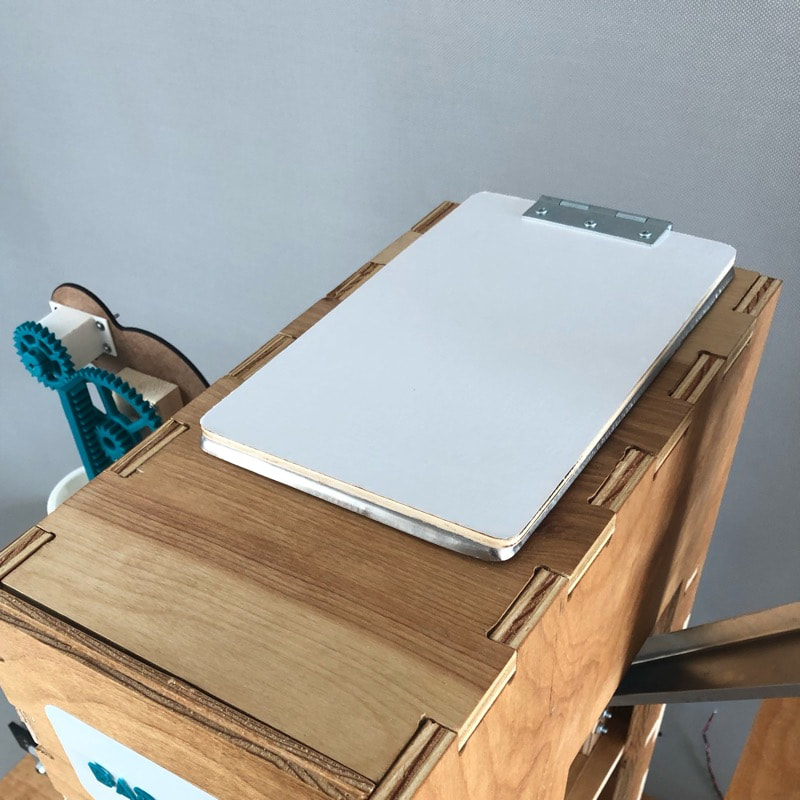

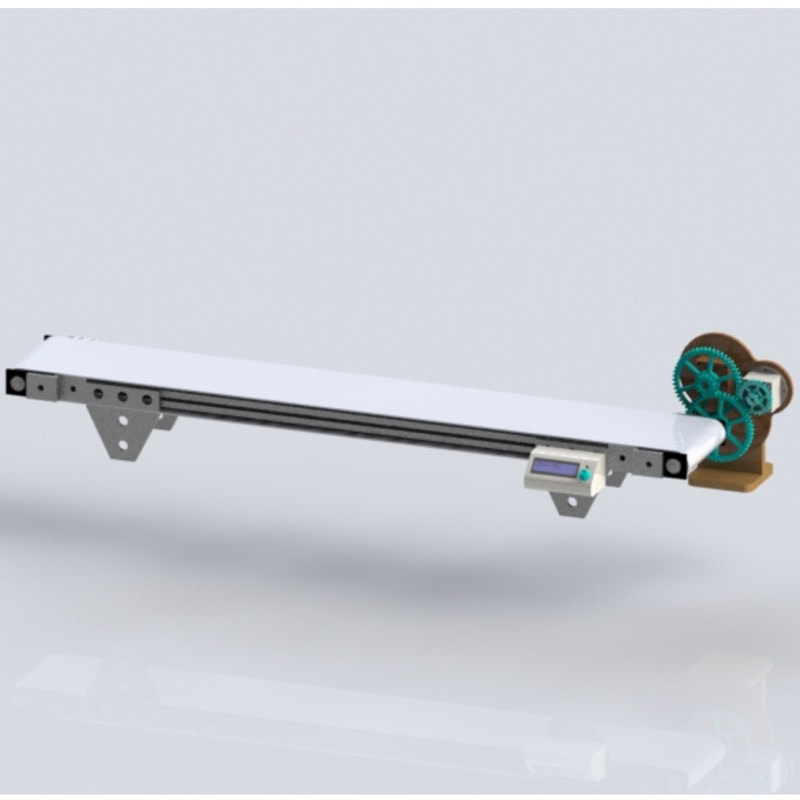

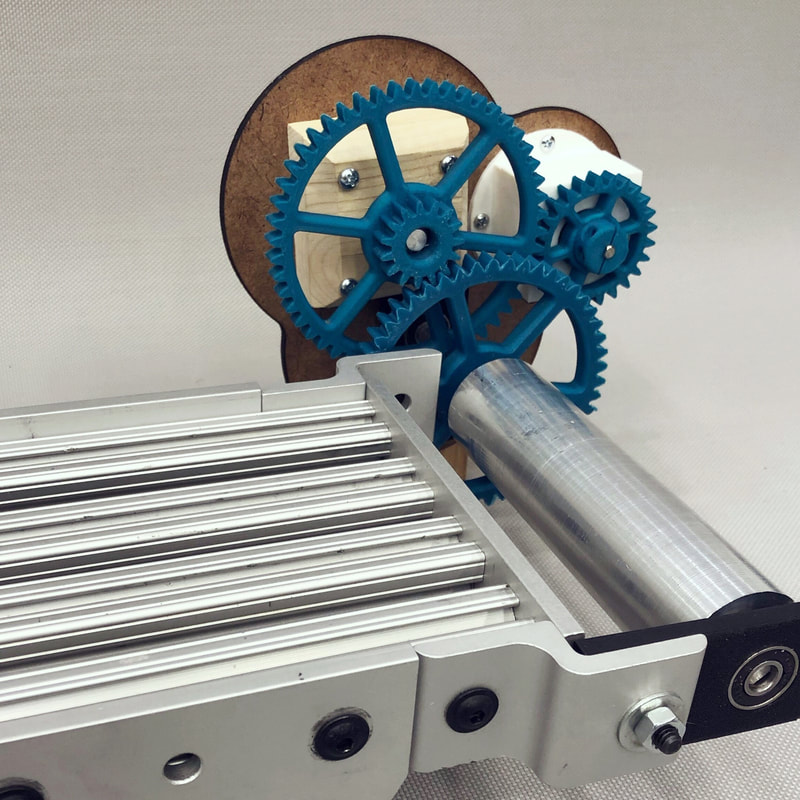

Filter ArmThis is a rack and pinion system driven by a stepper motor that moves the coffee filter cone in time with the pour system. During the pouring and drip stages, the filter cone stays under the water dispenser. It is then pushed forward by the rack. The filter-cone is attached to the rack with an adhesive cloth hinge, so it plunges forward and drops the filter over the edge. It is then pulled back slightly as the user replaces the filter, and pulled back into the pouring location.

|

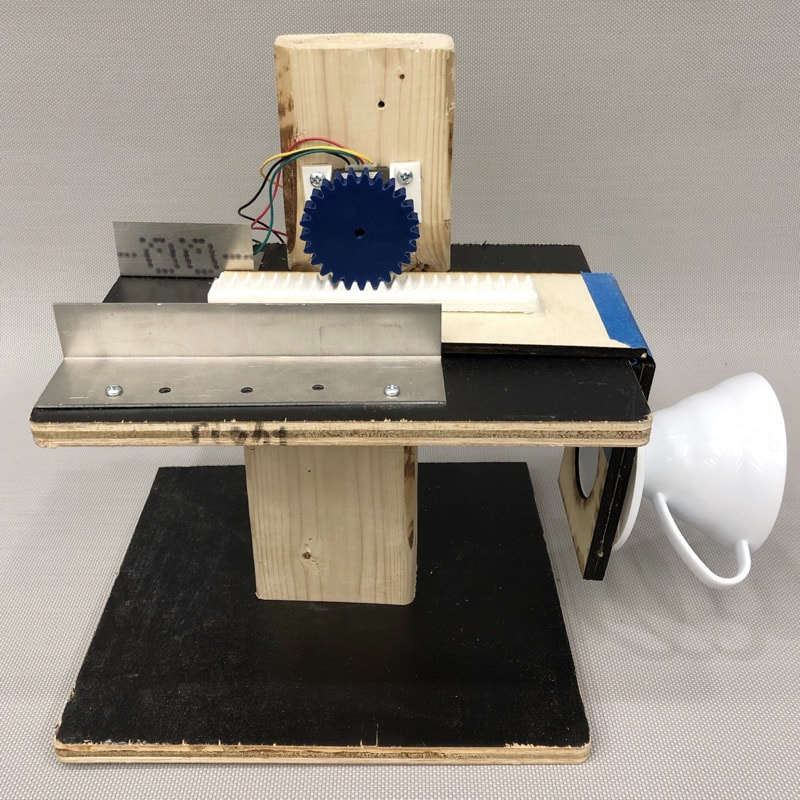

Cup DispensingThe cup dispensing system holds cups in a 3D printed housing and dispenses the cups with a 3D printed rack and pinion powered by a stepper motor. Sheet metal “fingers” provide just enough force to ensure a single cup is dispensed at a time. The system is mounted on a hardboard backboard and plywood tower.

|