Sprint Goals

Our goal this sprint was to have a functioning MVP. This meant that a basic mechanical system was built, the motor and the LEDs were connected and working in unison with the distance sensors. We also wanted to have at least two behaviors coded.

Current State

|

During this phase of the process we completed a minimum viable product. This was working before the video was recorded, however the motor stopped working and the circuit had a short in the process of improvement. The sensors have been connected to the system and the motor and LEDs will respond with it. The mechanical structure has been built and the cam is functional, with a clear plan to improve the system.

|

|

Lights

Here the LEDs have two set behaviors, if you are close it is scared and if you are far it is happy. There is a dome structure of over seventy LEDs that will be placed inside of the dome. The lights are being programmed together with the sensor and the motor, however the Arduino does not have enough memory for all of the code. This is likely the source of some of the problems in the MVP at the moment.

Motors and Sensors

The motor is running with the same two function as the LEDs with the sensors. The petals are being opened when the user is far away from the sensor and closed when they come close. Due to the heavy weight of the cam at the moment the motor has a bit of trouble, this will be fixed in the upcoming few weeks. Once again, the memory problem causes us to not be able to run the motor and the LEDs at the same time.

The Circuit

|

In this sprint a circuit was created on a protoboard, however this circuit suffered a few issues. The voltage regulators were wired incorrectly and there was a short in a different part of the circuit. The new components were ordered in order to create a new circuit, which will then also be wired to connect two Arduinos together, one for the motor and one for the LEDs.

|

Mechanical

|

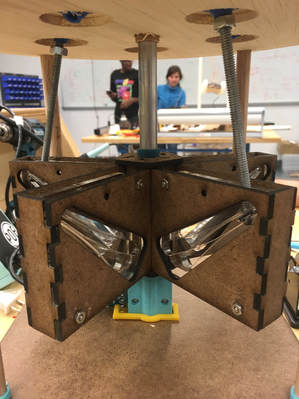

The cam was redesigned from the previous sprint in order to have lower friction (acrylic) and be easier to manufacture (laser cut). From here we found that the new model was better but too heavy and we would need to eliminate the use of the hardboard on the outside.,

The baseplate and the top plate were cut on the Shopbot in order to make cleaner cuts and have more rigidity than the hardboard used previously. The sensors were mounted to the outside of the baseplate and the skirt to contain all the system and the electronics began being designed. |

Teardrop Shell

|

The 3-D printing has been ditched since it was too much effort in the CAD and not really the vision that we wanted. We will most-likely turn to more geometric shapes such as polygons or at least have bends rather than a curve.

For this sprint, we used cardstock to create a more rigid form and will focus on creating a final vision using sheet metal in the next sprint. |

What we've learned

From this sprint we have learned that the combination of code for different aspects is very difficult, especially when written by different individuals. From the manufacturing of the cam we got to know more first hand the pros and cons of different ways of manufacturing a pieces. We found out the capabilities of an Arduino and that we will have to use more than one or a mega in order to have all the functionality that we desire. Finally, we learned that circuits can be buggy and that voltage regulators are more complicated than previously thought.

Next Steps

From this point on we had a lot to accomplish to reach our final vision. Mechanically we needed to create the petals on the sculpture as well as the shell around the base. Along with this we wanted to remake the base plate and top plate to be nicer and have better bushing fits. The cam has to go through a redesign in order to be lighter and easier for the motor to move. Electrically a new circuit must be made and we must figure out how to avoid the problems we have had. Finally, in software we want to develop some more behaviors and make sure that the LEDs and the motors will work together with the sensors.