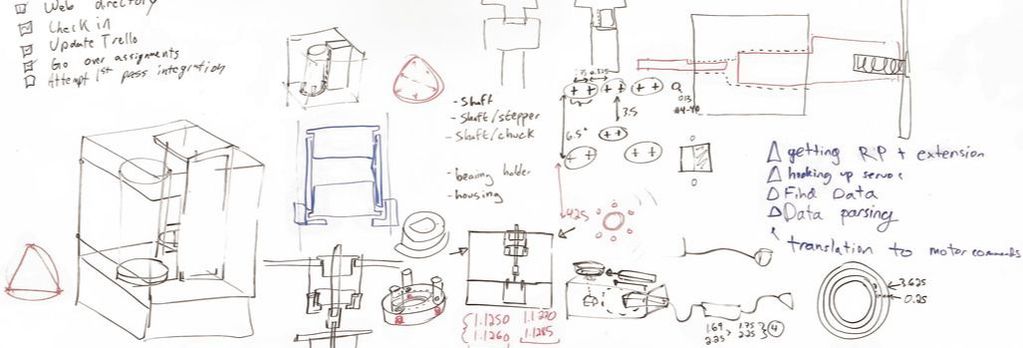

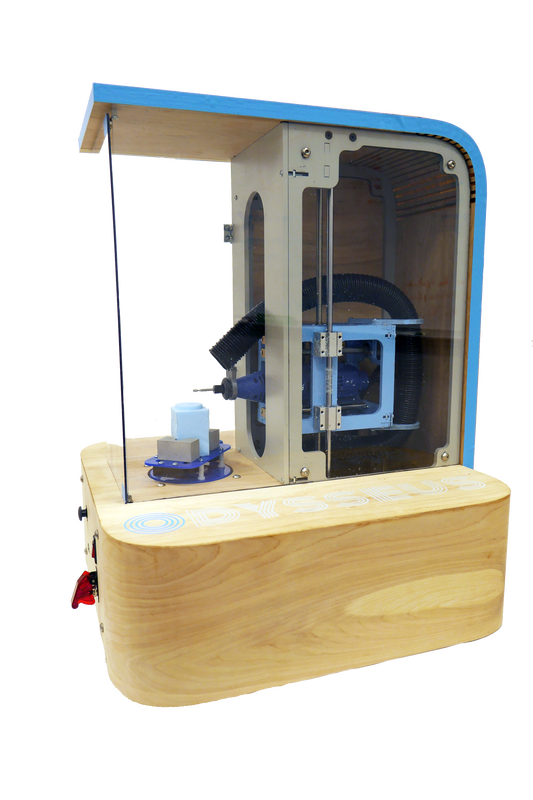

Process

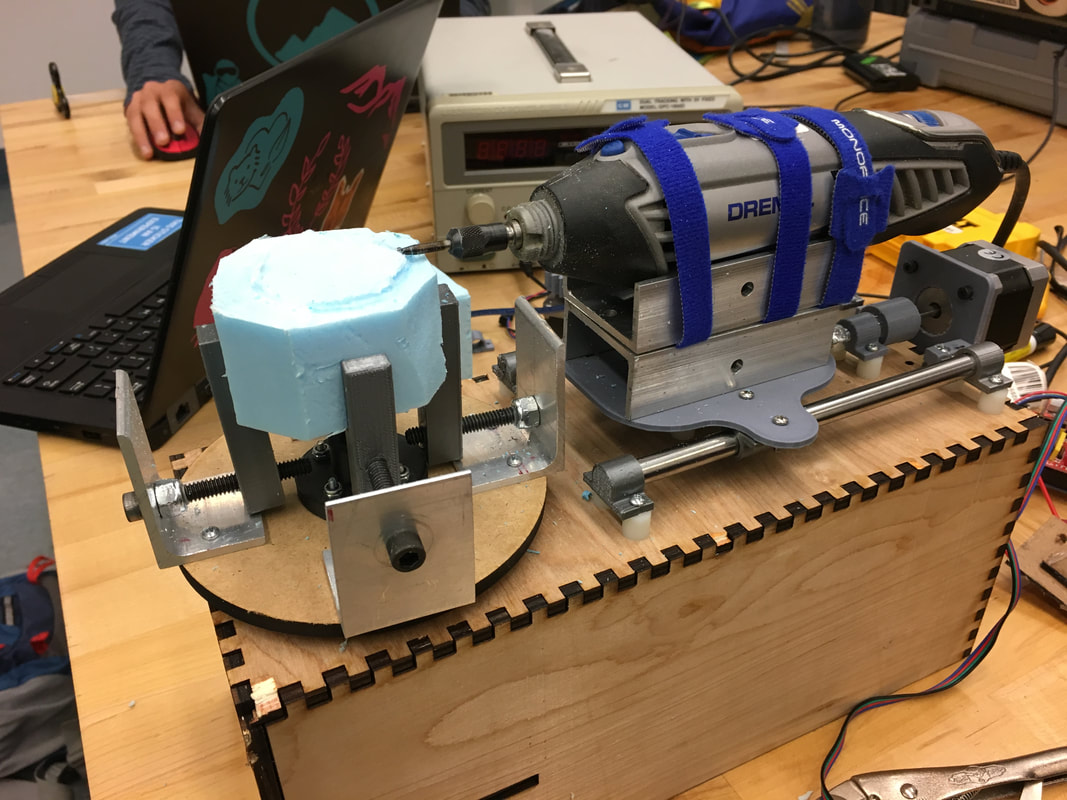

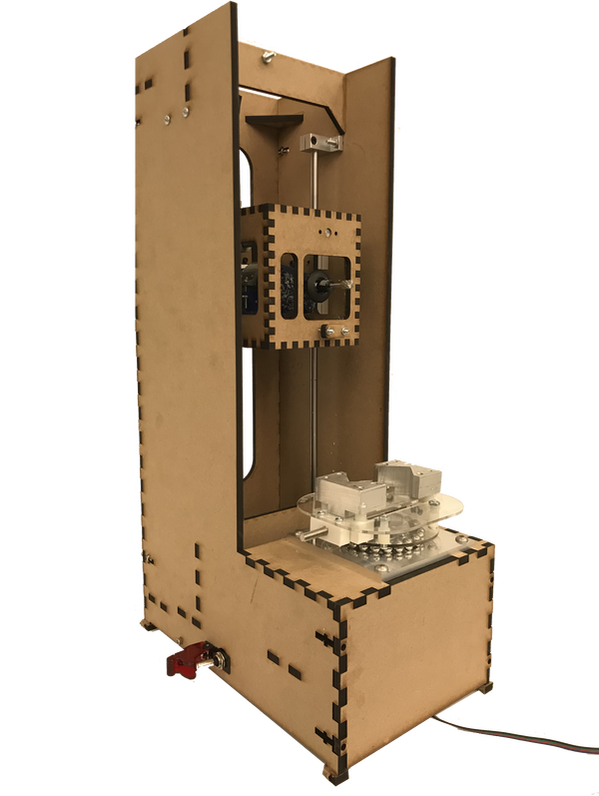

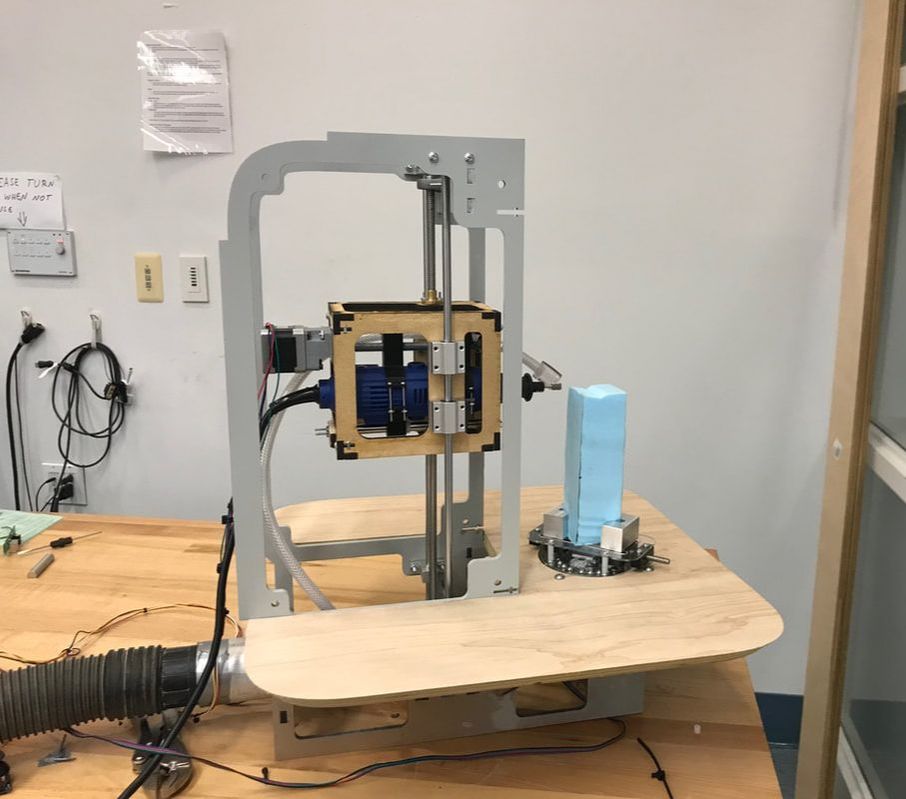

Sprint ONeSprint One - Two Axis

From the beginning, our vision for Odysseus was to have a fully functioning three axis CNC machine. To realize this goal, we had to validate our hypotheses in their most basic forms. We chose to focus on two of the three axis, assuming that adding height would be similar in concept to the horizontal dimension. We also validated our idea of using stepper motors to actuate our system. Our proof-of-concept testing was successful, and we were able to machine a circle. |