Look Ma, I can Fly!

Well, kind of. Our wings don't actually allow the user to take off, but they sure look out of this world. Check out the aesthetics page for info on the work behind making our wings look fly.

So, What's the Project?

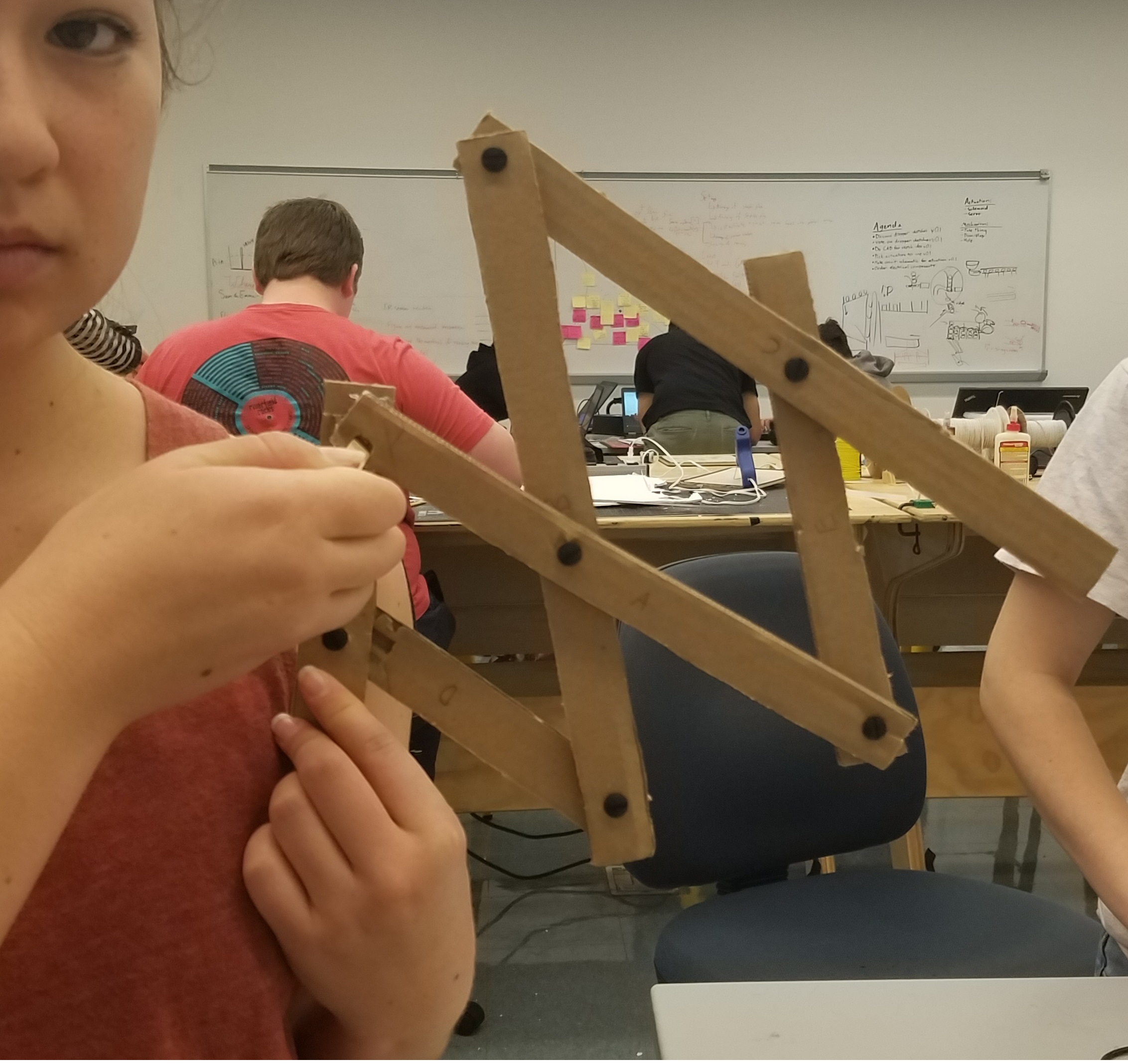

For our final project, we decided to create a wearable set of articulated wings that respond to environmental stimuli. Comfortable, lightweight, sturdy, and sparkly... What more could you want? Take a look at our About page to learn more about what we did.

Who is Daedalus

Surprisingly, our team is not composed of a mythical Greek inventor. However, we sure have the smarts of Daedalus with our team members Christina, Sophie, Margo, Siena, and MJ. More info on our roles and contributions can be found on the Meet the Team pages.

The Building of Our Articulated Wings

A simplified timeline of our two-week Sprints

Sprint 3: Integration and MVP

For this sprint we integrated the subsystems and assembled our final MVP. To accomplish this we improved the backboard, created sturdier motor mounts, integrated unltrasonic sensors, laser-cut thicker plywood wing 'bones', attached feathers, and sewed comfortable foam filled harness straps.