Sprint Goal:

Have an integrated product from GUI to needle motion.

Have an integrated product from GUI to needle motion.

Overview:

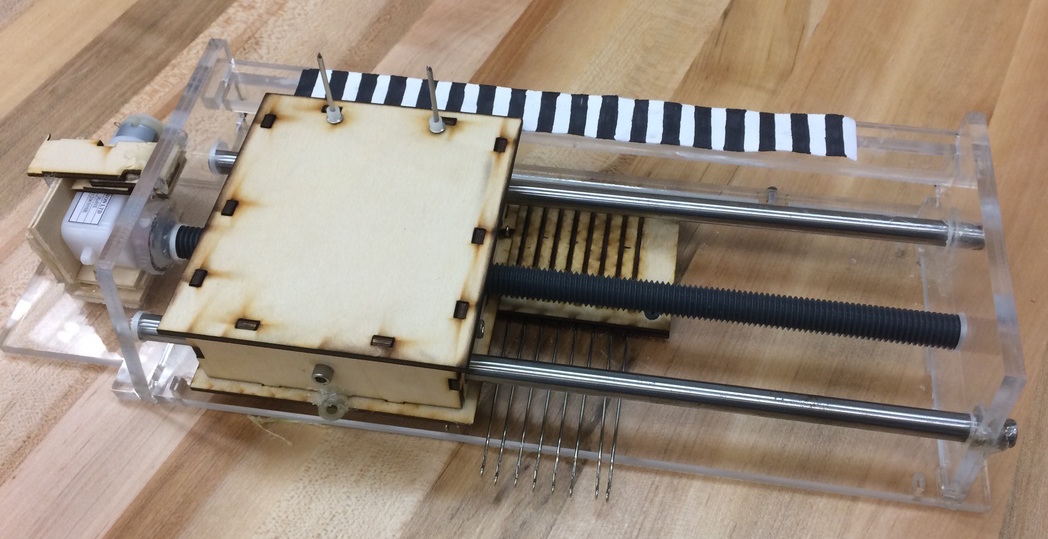

Project currently has carriage attached to chassis. The carriage includes a linear cam and attachment for the IR sensor circuit board. However, the current attachment arrangement is wobbly. Sensor code and rig missing functionality. Needle bed attached to chassis but cam and needle followers currently jam. Desktop GUI for scarf size is currently integrated to allow for user input to determine scarf parameters on the embedded system. However, motor currently only moves in one direction due to IR sensor code not being the latest version. Yarn too think for needles

Project currently has carriage attached to chassis. The carriage includes a linear cam and attachment for the IR sensor circuit board. However, the current attachment arrangement is wobbly. Sensor code and rig missing functionality. Needle bed attached to chassis but cam and needle followers currently jam. Desktop GUI for scarf size is currently integrated to allow for user input to determine scarf parameters on the embedded system. However, motor currently only moves in one direction due to IR sensor code not being the latest version. Yarn too think for needles

|

Sprint Events:

Event: Material and Design Meeting headed by Aubrey and Claire

Task: Website Blog Framework to be moderated by Joe HTML and CSS files exist in our Olin website folder. Blogs exist.

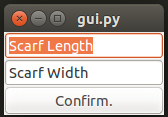

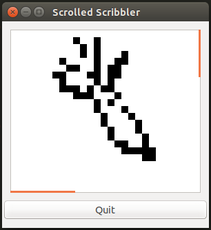

Task: 1-color GUI to be moderated by Sean First iteration GUI. Allows users to define size of scarf. Limits users to integers and limits size to number of needles in needle bed. GUI sends two user-determined ints via serial ports.

Task: 1-color Serial Receive to be moderated by Sean Arduino code to receive GUI input over serial port. Data is moved into usable variable.

Task: Sensor Code Beatification be moderated by Paul First iteration sensor code optimization attempt. Code commented. Motor directionality code included.

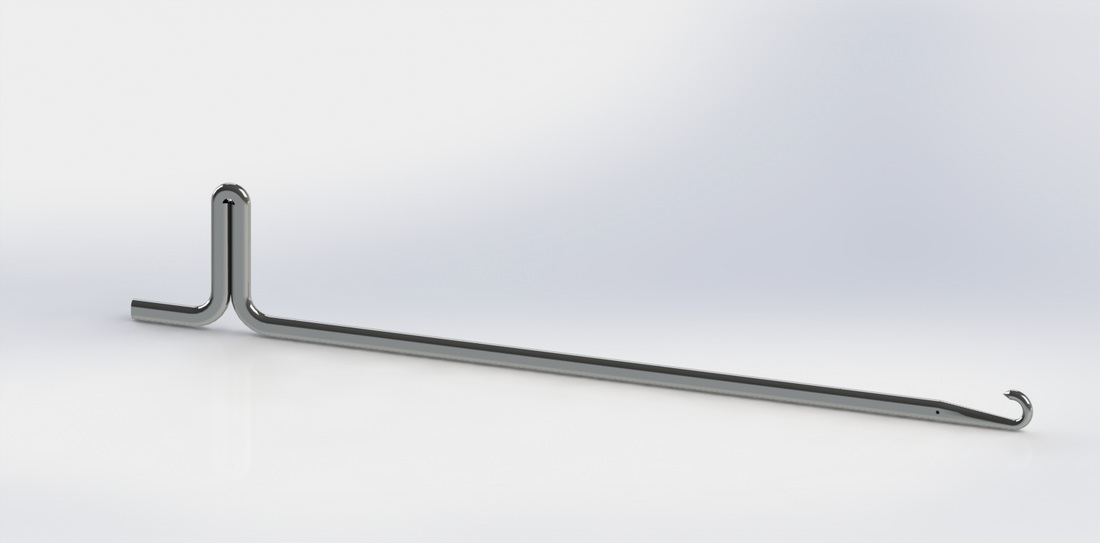

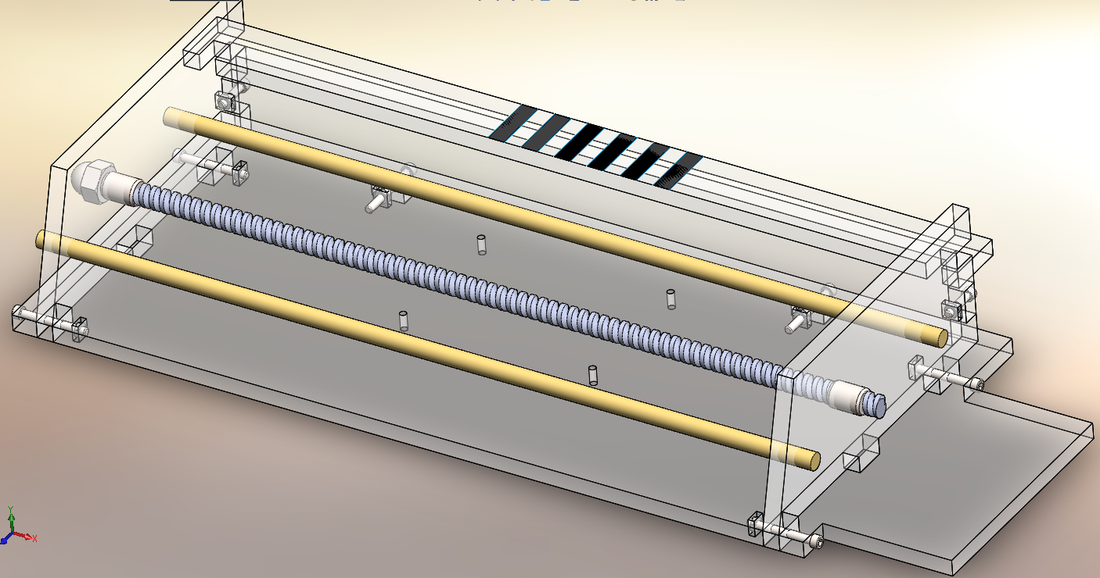

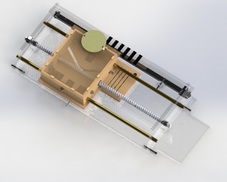

Task: Second Iteration Needle Bed to be moderated by Aubrey 10 needle acrylic bed. Horizontal needle positions consistent. Needles move smoothly within slots and allow for angled motion caused by cam. Attachable to chassis. Needles slide between 3 positions: stitch out, stitch in, and ignore.

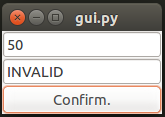

Task: Linear Cam Carriage to be moderated by Claire Carriage with 10-needle linear cam. Attachments for sensor circuit and chassis.

Task: Acrylic Chassis to be moderated by Claire Acrylic chassis with appropriate attachments for carriage, sensor strip, and motor

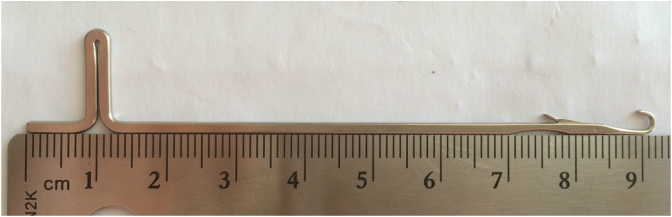

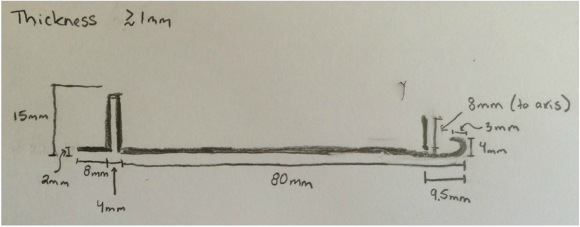

Event: Needles Arrive headed by Claire

|

Picture shown is from after system integration. Neither the motor nor the washer thread guide existed initially.

|

|

Task: 2-color GUI to be moderated by Sean

GUI allows pattern to be choose from clicking a grid. Grid slots can be selected or deselected. Allows users to define size of scarf. Limits users to integers and limits size to number of needles in needle bed. GUI sends user determined size and .pattern information over serial port.

Task: Formal Sensor Rig to be moderated by Paul Sensor circuit rig to track carriage position over needles on solder prototyping board. Has female pin headers for output/input/ground wires. Uses Arduino to track needle position.

Carriage Motor Code to be moderated by Claire Carriage moves back and forth across needle bed the number of times determined by size variable. Motor direction stored as variable for use by needle counter.

Task: Website Pages to be moderated by Joe Additional pages exist on website: who/about us, what/project description; recipes. HTML and CSS files exist in our Olin website folder. Relevant pages exist (can be empty).

Task: Color Change to be moderated by Aubrey First iteration yarn color changing rig. Assumed eventual attachment to carriage.

Task: Yarn Tensioner to be moderated by Paul First iteration yarn tensioner. Focus on tensioner placement to land over open needles and adjustability on applied tension on string. String should be held over needles.

Task: 2-color Pattern Serial Receive be moderated by Sean Arduino code to receive GUI input over serial port. Data is moved into usable variable.

Task: MS Paint App to be moderated by Sean GUI allows for color selection of yarn. Limits users to two colors. Visualize pattern with chosen colors.

Task: Motor Homing to be moderated by Paul At start up, Arduino homes to the right side. Uses Arduino and mechanical motor stops. Requires mechanical stops to be acquired.

Event: Chassis and Needle Bed Integration headed by Claire and Aubrey

Event: Full System Integration headed by Sean and Claire

|

"Bologna and orange marmalade? In my day, we just ate PB&Js." ~Grandma

"Oh no! Mr. Fluffles got in my yarn basket again. That silly cat." ~Grandma

|

Risks:

Currently the needle bed and cam do not play nicely together. The cam line is not held stable and the needles turn within their slots. This, in combination with the friction of the cam material causes the cam to jam mid-row. If we don’t fix the cam/needle relationship, we will be unable to make our minimum viable product. To mitigate this risk, we will focus our entire next sprint on needle/cam actuation. We plan to have each member of the team make multiple changes and iterations of the two parts in order to resolve the issue.

Currently the needle bed and cam do not play nicely together. The cam line is not held stable and the needles turn within their slots. This, in combination with the friction of the cam material causes the cam to jam mid-row. If we don’t fix the cam/needle relationship, we will be unable to make our minimum viable product. To mitigate this risk, we will focus our entire next sprint on needle/cam actuation. We plan to have each member of the team make multiple changes and iterations of the two parts in order to resolve the issue.

Decision:

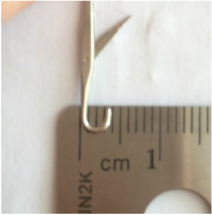

We have decided to focus on a stable, simple system over the original many features approach in order to ensure basic functionality. If we do manage to get basic functionality working, we will additionally work to create a color changing system. We have completely dropped the idea of using purl stitches due to the complexity of the mechanical system needed to make this possible. We plan to approach this by making as many iterations as possible as quickly as possible to find a solution to the cam/needle mismatch. We additionally found that the needles are of a size they split worsted yarn. To resolve this, we plan to use light worsted or fingering yarn weights.

We have decided to focus on a stable, simple system over the original many features approach in order to ensure basic functionality. If we do manage to get basic functionality working, we will additionally work to create a color changing system. We have completely dropped the idea of using purl stitches due to the complexity of the mechanical system needed to make this possible. We plan to approach this by making as many iterations as possible as quickly as possible to find a solution to the cam/needle mismatch. We additionally found that the needles are of a size they split worsted yarn. To resolve this, we plan to use light worsted or fingering yarn weights.

Next Sprint:

Goal: Automatically produce a small multiple row knit test piece

For the coming sprint we plan to:

Goal: Automatically produce a small multiple row knit test piece

- We assume that once the issue of cam/needle partnership is resolved, creating a small sample piece will be trivial.

For the coming sprint we plan to:

- Update the needle bed to have correctly sized slots to allow needles to be placed in the off position,

- Update the needle bed to keep needles upright in slots,

- Rigorously attach the motor to the chassis,

- Bridge the linear cam slot to increase its stability,

- Lower the friction between linear cam and needles by adding slicker materials,

- Lower the friction between linear cam and needles by adding rollers to the needles’ cam followers,

- Add a needle guide to aid needles moving into the cam correctly,

- Add counting and rigor to the sensor rig and code, and

- Add accessories such as yarn guides and the yarn comb to allow for the small sample piece to be made.