Sprint Goal:

Initial attempt will be made on all project components.

(Project components: Needle Bed, Chassis, Carriage, Motor Control, Location Detection, Desktop GUI, and Website)

Initial attempt will be made on all project components.

(Project components: Needle Bed, Chassis, Carriage, Motor Control, Location Detection, Desktop GUI, and Website)

Overview:

First iterations of chassis, carriage, and position sensor created and integrated. Motor unconstrained and must be held by hand. Speed of carriage very slow. First iteration needle bed created but not integrated. Work on GUI code begun but not functioning/integrated. Framework of website created in WIX. Next time we will focus on total project integration.

First iterations of chassis, carriage, and position sensor created and integrated. Motor unconstrained and must be held by hand. Speed of carriage very slow. First iteration needle bed created but not integrated. Work on GUI code begun but not functioning/integrated. Framework of website created in WIX. Next time we will focus on total project integration.

|

Sprint Events:

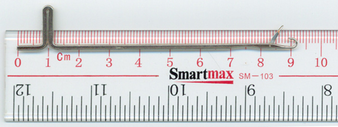

Task: Order Latch Needles to be moderated by Claire

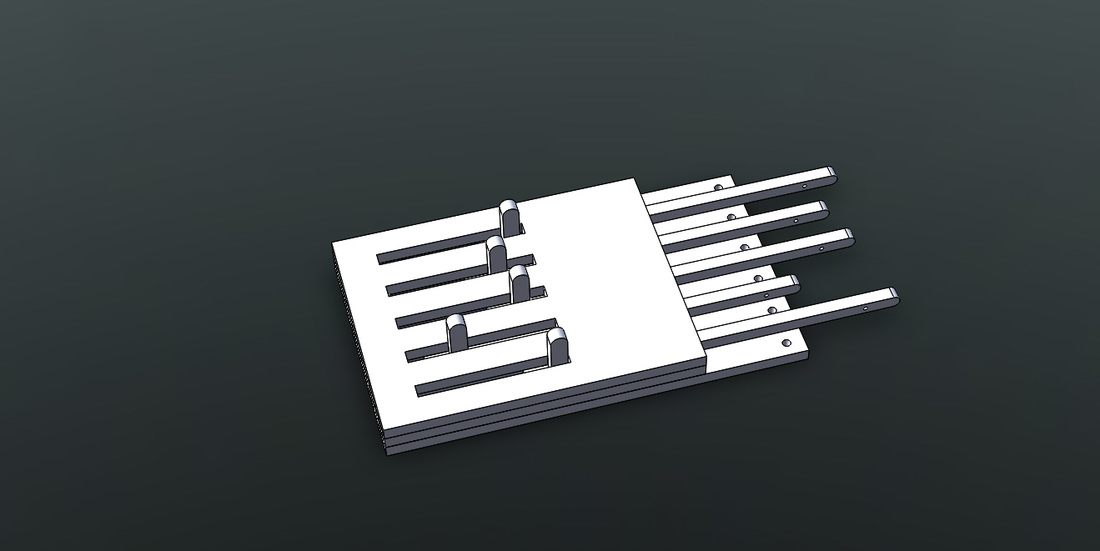

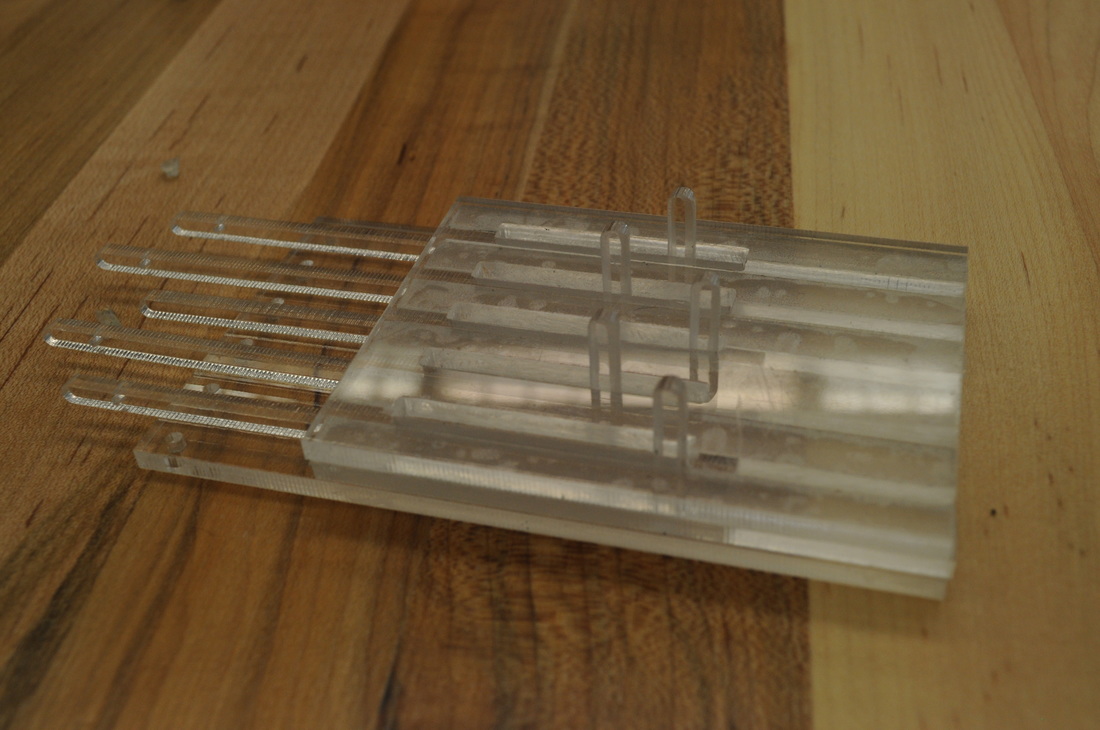

Event: Linear Cam Sketch Model headed by Sean

(First iteration of needle bed sized for 5 mock needles. Should include mock needles with cam followers. Laser cut from acrylic. Needles are held individually such that the cam followers are upright. Needles can glide smoothly on bed.)

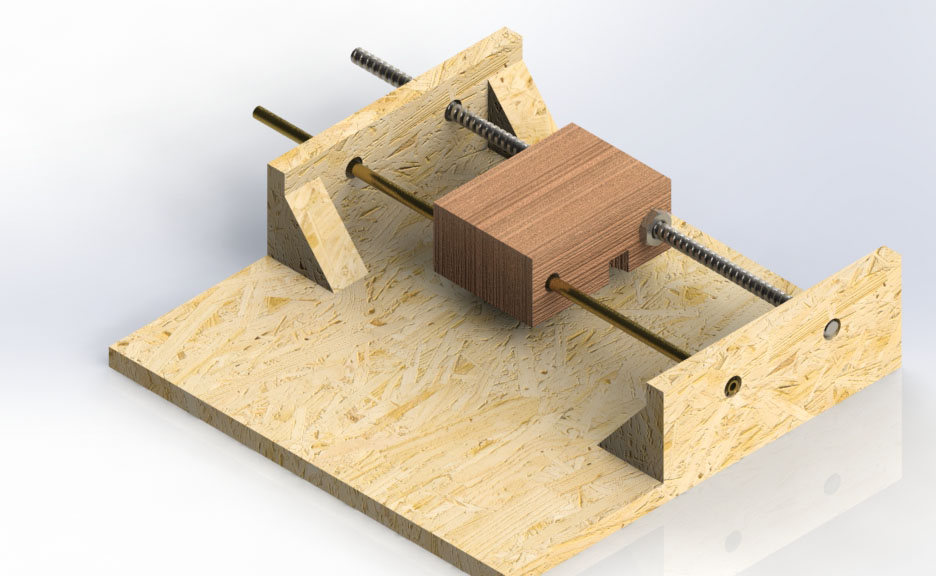

Tasks: First Iteration Chassis and Mock Cam to be moderated by Claire First iteration of carriage and chassis. Mock carriage with linear cam to cause motion of mock needles. Hook up motor rig for linear motion to Arduino.

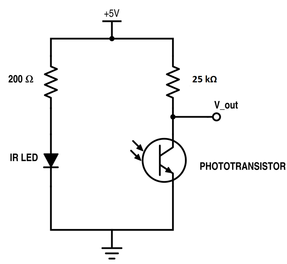

Task: First Iteration Sensor Rig to be moderated by Paul First iteration sensor rig to track carriage position over needles. Arduino should output correct number of needles passed to serial monitor when motion is in one if not both directions.

Task: Website Framework to be moderated by Joe Blog-style website framework allows for post/updates page, project description page, team page, etc; Adding embedded images, videos, etc should be worked out. Should be ready for other members to start adding project info to update page. First draft of project information ready for peer review.

Task: 1-color GUI to be moderated by Sean First iteration GUI. Allows users to define size of scarf. Limits users to integers and limits size to number of needles in needle bed. GUI sends two user-determined ints via serial ports.

Event: Sensor and Carriage Integration headed by Paul and Claire

|

"How old are you now? Ten? Eleven?" ~ Grandma

“And it won’t move? It’s all this technology you’ve tried to use. What you need is a good, quality woodsmith.” ~ Grandma

“Young people these days are far too impatient.” ~ Grandma

“Don’t forget to wash behind your ears” ~ Grandma

"A carriage? Where is the horse? How does one get anywhere in that strange contraption" ~Grandma

"Now that's a pace I can understand. Normally you young folks are in a rush to to everything." ~Grandma

"What are you typing? That looks like gibberish." ~ Grandma

|

Previous Goals:

We desire to have a knitting machine with multiple feature capabilities such as multiple stitch types (purling and knitting), multiple colors patterns in a single garment, and possibly lace-patterning. The trade-off is a less polished final product with possible jankiness used to hold the machine together and allow for the expanded functionality. Our individual learning goals include learning about graphic user interface (GUI) creation, practice in machining, and improving our knowledge about mechanical joints and linkages.

We desire to have a knitting machine with multiple feature capabilities such as multiple stitch types (purling and knitting), multiple colors patterns in a single garment, and possibly lace-patterning. The trade-off is a less polished final product with possible jankiness used to hold the machine together and allow for the expanded functionality. Our individual learning goals include learning about graphic user interface (GUI) creation, practice in machining, and improving our knowledge about mechanical joints and linkages.

Risks:

We assumed that the known mechanical system of a linear cam carriage and needle bed with cam follower needles will work as described. However, the needles in needle bed oppose motion that is not parallel to the slots. If our rendition of the system doesn’t work as expected we have no backup plan for creating the system. To mitigate this risk, we will focus on getting our system integrated completely in order to test the system and make any corrections that are necessary.

We assumed that the known mechanical system of a linear cam carriage and needle bed with cam follower needles will work as described. However, the needles in needle bed oppose motion that is not parallel to the slots. If our rendition of the system doesn’t work as expected we have no backup plan for creating the system. To mitigate this risk, we will focus on getting our system integrated completely in order to test the system and make any corrections that are necessary.

Decision:

We have decided to focus on integration and stability in order to ensure basic functionality. This likely means each iteration will be more formally made to ensure parts fit together.

We have decided to focus on integration and stability in order to ensure basic functionality. This likely means each iteration will be more formally made to ensure parts fit together.

Next Sprint:

Goal: Integrated product from GUI to needle motion within bed.

Improvements for the coming sprint:

Goal: Integrated product from GUI to needle motion within bed.

- With this level of integration and functionality, we should be able to focus on stitch actuation for sprint 3.

Improvements for the coming sprint:

- Update the needle bed to accommodate the size of the real knitting machine needles which are thinner than our acrylic sheet mock needles,

- Update the needle bed to allow for needles to be in an off position, aka not get caught by the carriage so that scarves can be of varying widths without half stitches being formed,

- Purchase a threaded rod with greater distance between threads to allow for faster motion of the carriage,

- Attach the motor to the chassis such that we do not have to manually hold the motor to allow for motion,

- Add counting and an attachment method to the sensor rig and code, and

- Make GUI data available to the Arduino