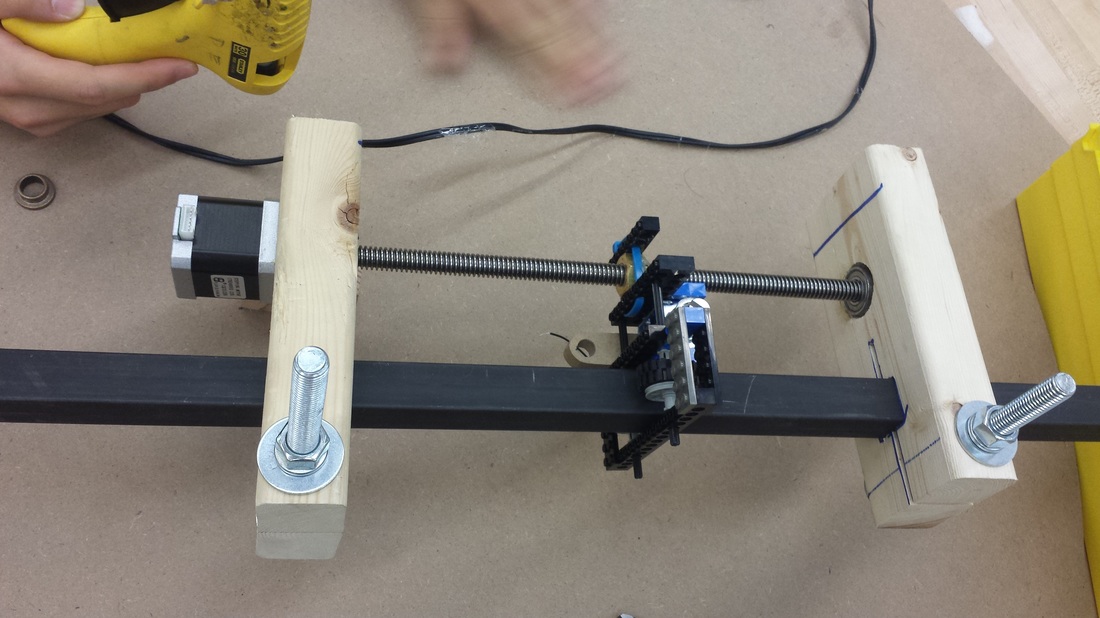

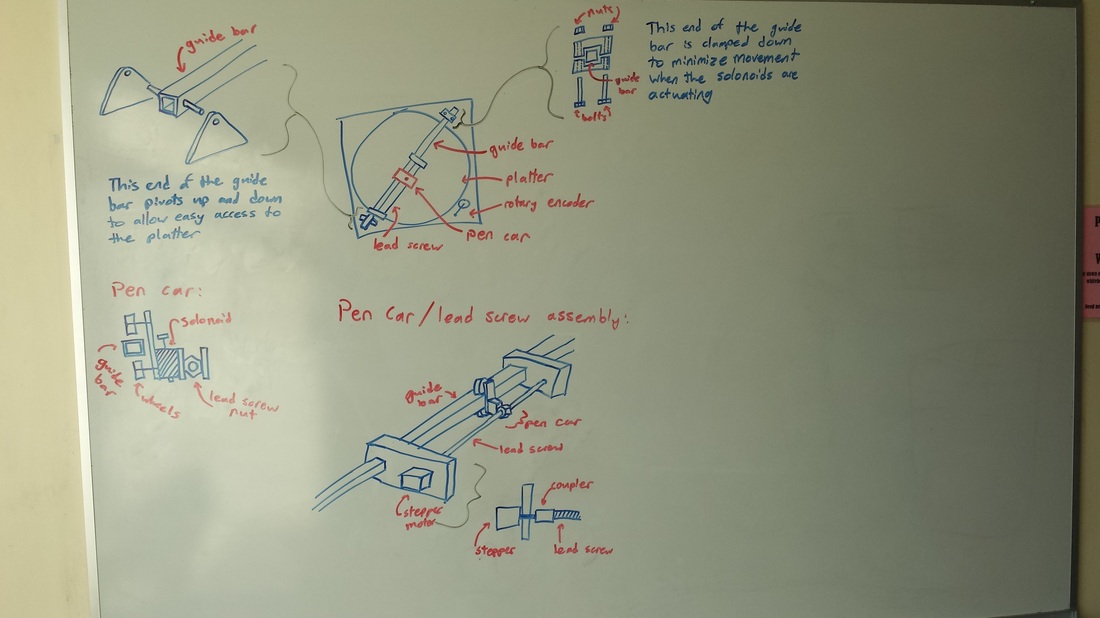

So as you can see, we put together our Sprint 3 deliverable. Unfortunately, our design pivot left us short on time to make our subsystems integrate prettily or make sure our motor could turn the new, heavier wheel.

What's really exciting is that we have all our subsystems independently working with proof that they can integrate. In the above video, you can see Kai hit the limit switch and start the stepper motor and solenoid's programmed drawing pattern. Although not visible in the video, we also have a rotary encoder that tracks rotation of the wheel, although we're still experiencing slippage.

Our wheel is also now safer, tangle-free, and (supposedly) driven by our DC motor underneath with three guide wheels to provide support for the rotation.

In our next sprint, we're going to address potential risks in lack of precision, trouble integrating, messy wiring, lack of electrical power, parallel processing, and strength of motor. We want to minimize these risks by integrating early, finalizing our design quickly(no more pivots), keeping clean circuit hygiene, specifying our parts quickly, using interrupts in our code instead of delays, and potentially driving our wheel from the side or changing our wheel material.

We'll be buying parts over Thanksgiving break to try and eliminate wait time so we can start working ASAP.

Til next time!

-Mackenzie

What's really exciting is that we have all our subsystems independently working with proof that they can integrate. In the above video, you can see Kai hit the limit switch and start the stepper motor and solenoid's programmed drawing pattern. Although not visible in the video, we also have a rotary encoder that tracks rotation of the wheel, although we're still experiencing slippage.

Our wheel is also now safer, tangle-free, and (supposedly) driven by our DC motor underneath with three guide wheels to provide support for the rotation.

In our next sprint, we're going to address potential risks in lack of precision, trouble integrating, messy wiring, lack of electrical power, parallel processing, and strength of motor. We want to minimize these risks by integrating early, finalizing our design quickly(no more pivots), keeping clean circuit hygiene, specifying our parts quickly, using interrupts in our code instead of delays, and potentially driving our wheel from the side or changing our wheel material.

We'll be buying parts over Thanksgiving break to try and eliminate wait time so we can start working ASAP.

Til next time!

-Mackenzie

RSS Feed

RSS Feed