Sprint 1 - One Axis

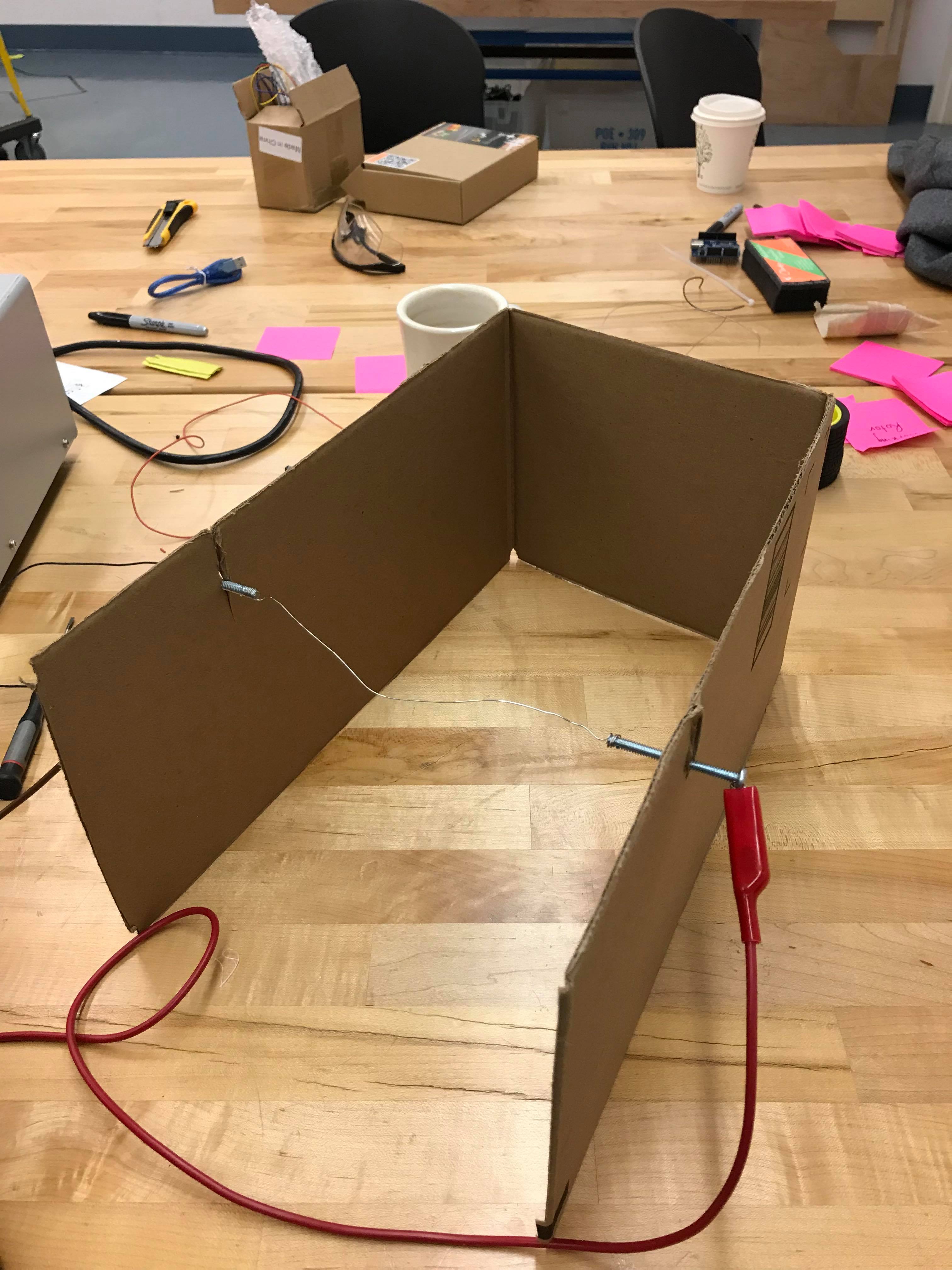

We first built a prototype wire cutter out of cardboard to understand the capabilities of the nichrome wire through testing. Then we focused on building a one axis gantry system that would be able to cut through foam moved by stepper motors on a belt and pulley drive. We chose to use linear rails and bearings over 80-20 extrusion for our gantry because of cost and aesthetic. The stepper motors were controlled through Arduino code and the wire was powered by an external power supply. We were able to validate our proof-of-concept by cutting a straight line through a block of foam.

Sprint 2 - Three Axis + Ventilation

We prioritized finding a solution to effectively filter and vent out the toxic fumes that were generated by the hot wire melting polystyrene foam because of safety. We created an enclosure that pulled air through a HEPA filter and carbon pre-filter using two fans mounted to the top. We also added the second and third axis that allows the wire to move vertically and the foam to rotate. While we did encounter some mechanical problems, this system functioned well enough to allow for extensive electrical and firmware testing in future sprints.

Sprint 3 - G-Code Generation + Power Integration

Because we had already achieved the mechanical MVP in the last sprint, we left the system intact so that the electrical and software subteam could focus on improving the electronics and code. \ Previously, we only had the ability to cut objects in straight lines, but over these weeks we were able to get the functionality to cut in a curve and also rotate to base. In addition, to move the motors we had to either move them individually or handwrite G-code to direct them, which was fairly inefficient. In these weeks we devised a methodology to move from a shape in something like Solidworks and converting it to G-code automatically, which made it a lot easier to cut more interesting shapes, such as the bunny ears as seen in the video below. We also integrated a 12 volt power supply to control every electrical component.

Final Product - 4-Axis CNC Hot Wire Cutter

With everything CADed and power integrated, all that was left was final fabrication and assembly. We focused on the aesthetics to present a clean, well-designed project that looks as nice as it functions.