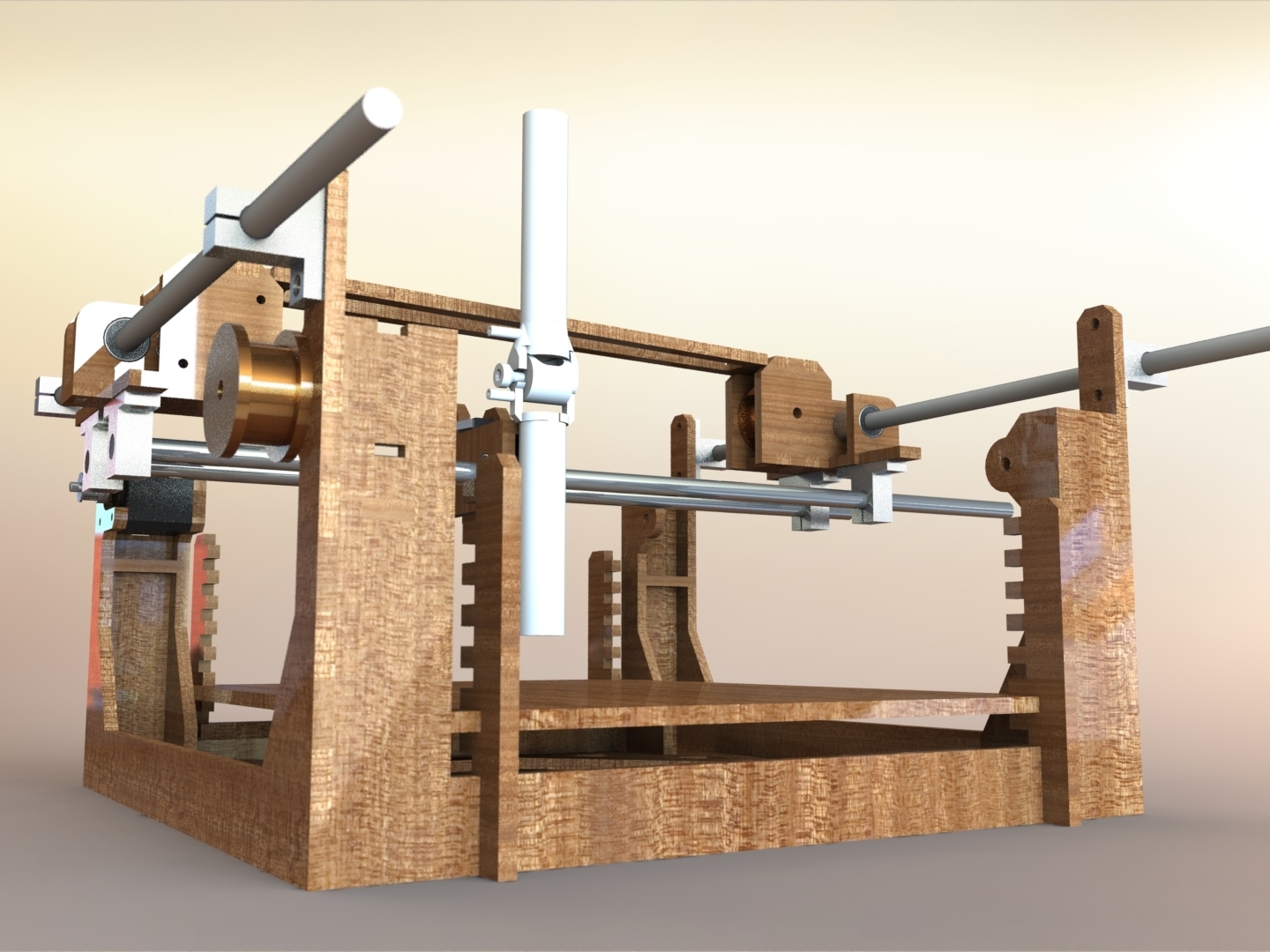

Gantry

The M&Ms are placed with the help of a pulley-powered gantry that can put the dispenser anywhere on the surface within a few millimeters of precision.

The M&Ms are placed with the help of a pulley-powered gantry that can put the dispenser anywhere on the surface within a few millimeters of precision.

The computer program that powers this device spans two languages and two computers to deconstruct images into M&Ms and turn that image into a real design.

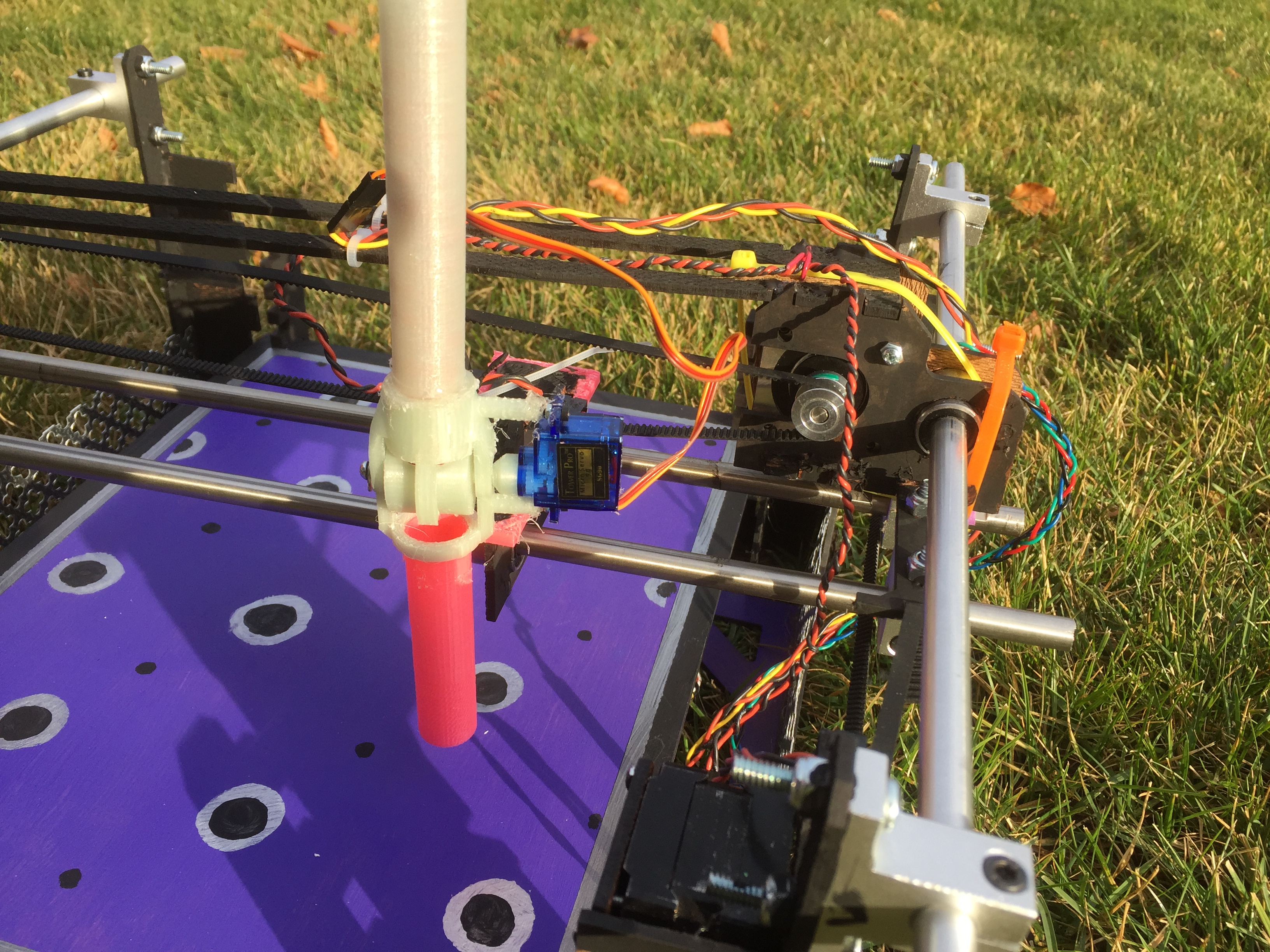

To create the picture, we needed a device to reliably deposit M&Ms from a container onto the surface. The result is a 3D printed servo-powered M&M dispenser.

Our final system comprises two stepper motors and a micro servo, all of which are controlled by an Arduino Uno connected to a laptop.

Watch the device run, look at pictures it has produced, and examine its inner workings. It's really cool, I promise.

Who are we? Why did we do this? None of us are really sure, but we'll gladly tell you what we do know.

This machine took five undergraduate students seven weeks to design and build. Find out what makes it so complicated and how it even functions.

Want to build something like this yourself? Or maybe you're just curious? Either way, we'll tell you all about how we did it.

Yearn for a more in-depth description of our process? Then check out our blog, written even as the story unfolded.

In case you weren't aware, this machine was built for a project at the Olin College of Engineering. Why not check out some other projects and info from our school?