Sprint 2

More in-depth work with new ingredients

More Touchscreen Problems

During the second sprint, we did further work on the pan-tilt mechanism and the touchscreen. We purchased an adapter for the touchscreen, which allowed us to get a first pass implementation of user input into MATLAB. We struggled during this process with getting the touchscreen to output accurate coordinates of the point of contact, but were able to solve this by adding pull-down resistors to make the touchscreen more sensitive.

CAD, Servos and Laser Test

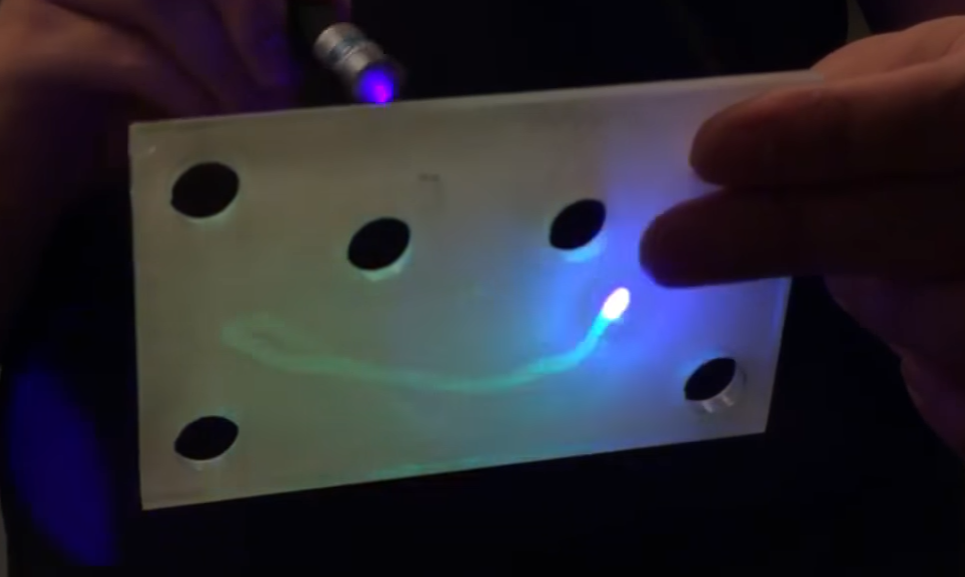

We also produced an initial CAD of the pan-tilt mechanism. This design required a very small, high-speed, low-torque servo and a larger, higher-torque servo capable of rotation through 360 degrees. To achieve 360 degree rotation, we decided to use a 2 to 1 gear ratio, allowing us to purchase a cheaper and more reliable standard servo, rather than one designed for continuous rotation. For this prototype, we mounted a small laser on the mechanism. However, when we finally tested the laser on a phosphorescent surface, nothing happened.

...Whoops.

This was a pretty major oversight, so we quickly researched options for lasers. We searched for a higher power laser that would be safe enough for use in a consumer grade product, but found that the wavelengths required to pass the energy threshold of phosphorescent response were much less eye-safe than our first diode. We eventually found a better laser, but it was much bulkier and emitted a near-UV, fairly unsafe wavelength. In the future, we would need to redesign the pan-tilt for this new laser and consider ways to protect the user from the high-energy UV beam.