Goal

Our sprint two goal was to develop a system that could mill a simple, continuous design by receiving continuous gcode commands over serial.

Demonstration

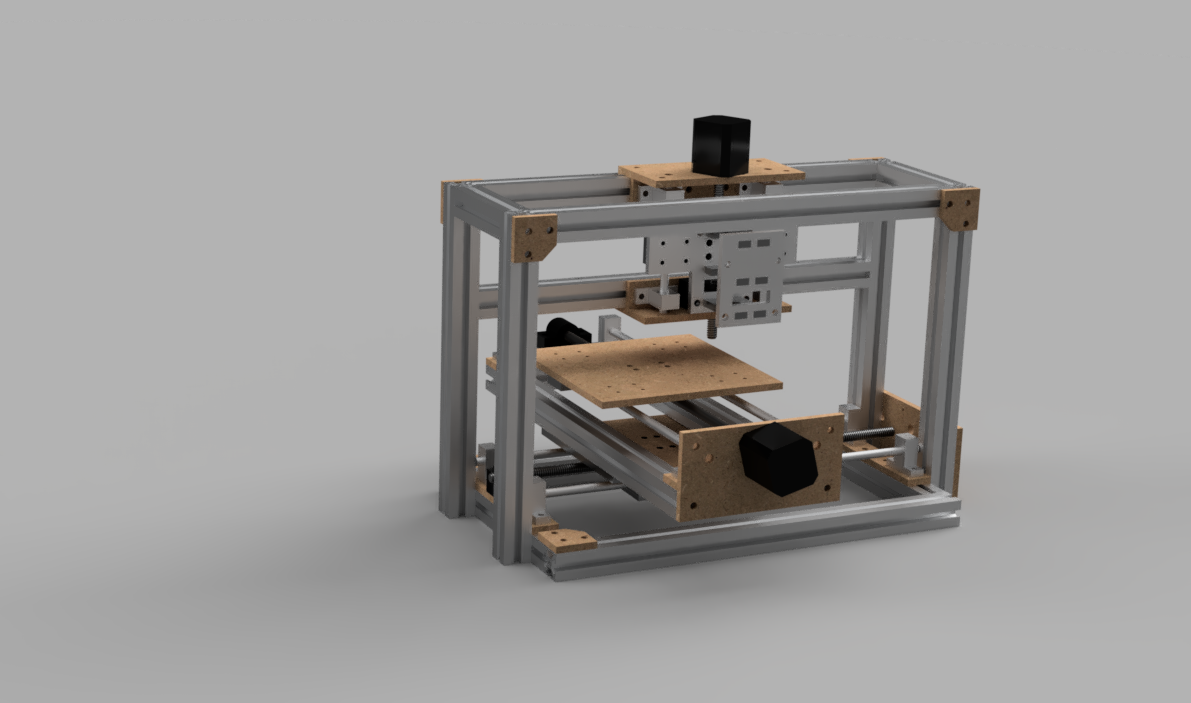

Mechanical

In sprint 2, we rebuilt the compound table to separate the linear motion rails from the frame and incorporate the Z axis with a stationary cutting tool. We also integrated with spindle motor by creating a laser-cut prototype motor mount.

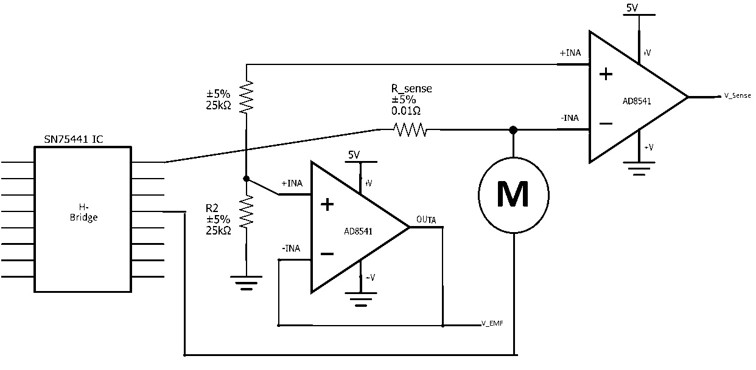

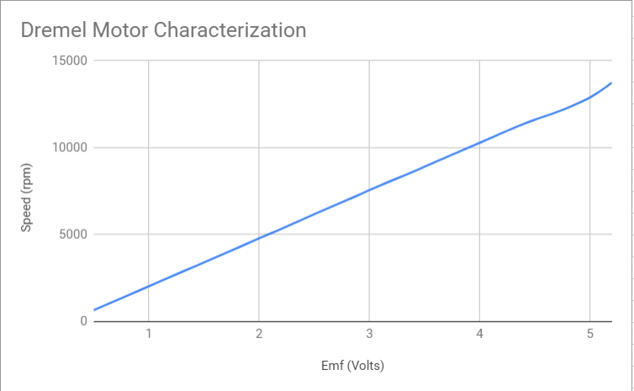

Electrical

For Sprint 2, we configured the z-axis motor with the help of tachometer. To complete this task, we developed a preliminary sensing circuit to drive the motor.

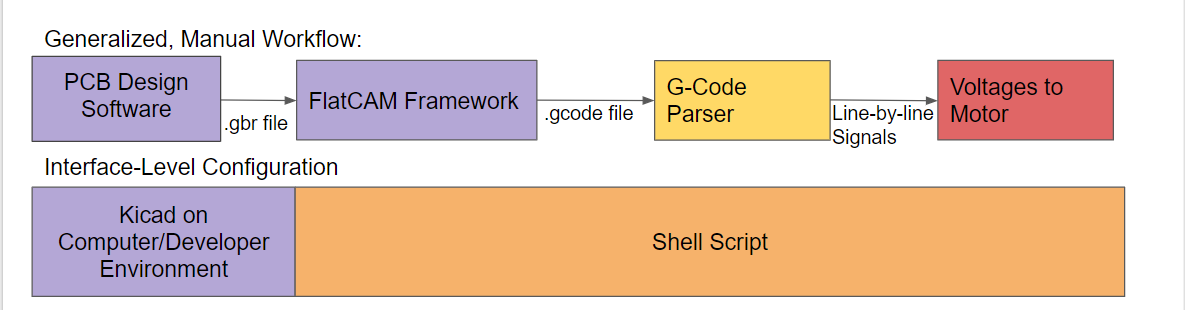

Software

We produced a Python script that formats the non-standard gcode generated by our path-traing framework (FlatCAM) into standard gcode for the Arduino to parse. We also produced another Python script that reads in a correctly formated gcode and sends commands to the Arduino line by line, even though there lacks some form of handshaking between the PC and the Arduino . In the spirit of developing a self contained environment, we also worked on using a Raspberry Pi into our system as our main compute unit instead of a laptop. Challenges We Encountered are that Flatcam has a unique internal scripting framework and set of operational modes that make it difficult to create command-line interfaces and that adapting tools meant for other computing frameworks for the Raspberry Pi is often quite difficult.