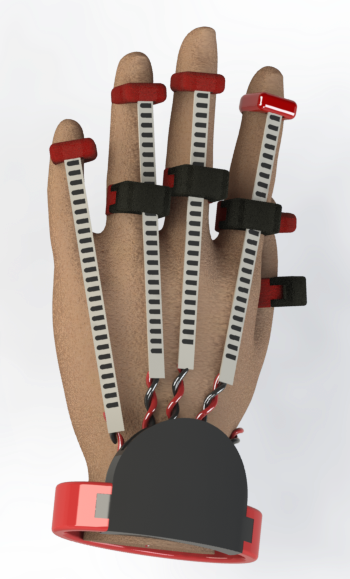

The integration of hardware and electrical components was designed in a minimalistic fashion shown in the figure to the left. We made this design with a consideration that the user might not always want to wear a glove while using the product.

The ring that goes on the tip of each finger is made from NinjaFlex and has a pocket on one side for the flex sensor. This ring only requires NinjaFlex, a thermoplastic elastomer, because the NinjaFlex material would allow enough friction to keep the sensor in place.

In this design, the inner rings are made from NinjaFlex and ABS, from the MakerBot 2X’s. This allows the ring to be able to form comfortably over the finger, because of the NinjaFlex, and have the abs track remain relatively frictionless, due to the ABS, to allow the sensor to move freely.

To contain the electrical components we made a bracelet-like component that contains the smallest electrical components that we could find. The bracelet itself is made of both NinjaFlex and ABS. The NinjaFlex allows the bracelet to comfortably wrap around the user’s wrist while the ABS gives enough structure to contain the inner components and reduce friction on the wires.

After going through many minor prototype designs we landed on this final design, seen at the right. We decided to eliminate the rings since they were bulky and hard to handle. Instead, we sewed pockets on the interior of the glove so that we could secure the sensors but still be able to adjust them.

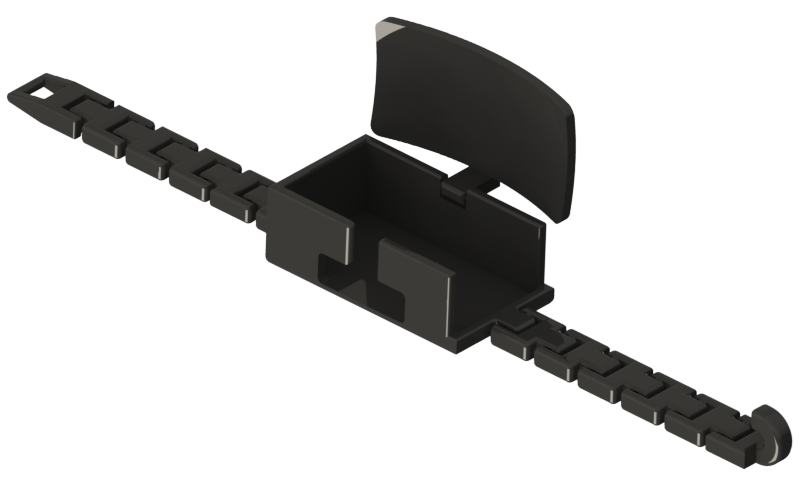

The second major design change was the bracelet design. Since we didn’t have access to NinjaFlex, we had to redesign the bracelet so that it would instead have linkages to form around the user’s wrist, as seen in the picture above. This led to a watch-like design (made from PLA - plastic used in the MakerBot 3D Printer) with an opening on the left side to allow the USB connector to be accessed. There is also an opening on the top edge of the bracelet to allow the wires to go through. The bracelet clasp is a basic hook design that is meant to be easy to use and durable. To avoid long assembly time, we made the rods of the linkages into cones so that we could print the entire design in one huge assembly print. The cones allowed minimal support material to be used while still constraining the linkages to keep them together. To contain everything we added a hinged cover that is easy to open and close. The reason the cover is curved is because it allows slack for the electrical components, so the wiring won’t break off, while still keeping the box dimensions at reasonable measurements. This design is meant to be comfortable, easy to fabricate, and easy to access the electrical components.

© Hextal. All rights reserved. | Design by TEMPLATED and Annabel Consilvio.