Design Process

Project Approach

Our team used the Scrum development process to create a finished system by iterating through successive minimum viable products. After picking our initial concept - a skeet-shooting paintball turret - and setting a goal of creating a system with unusually high production value, we embarked on our first sprint. To track and organize our work, we relied on Pivotal Tracker, an online productivity tool intended for use with Scrum. Code and CAD was stored in a central repository on GitHub, while meetings were coordinated over email. The duration of our work time comprised four two-week sprints, after two of which we presented our progress to our classmates in a design review which allowed us to receive constructive feedback. With this process infrastructure in place, we thought we had all the framework needed for a successful team project… but while we wound up in a good place, the process did not always flow exactly as intended.

Safety Procedures

Scope and Rapid Prototype (October 28th, 2014)

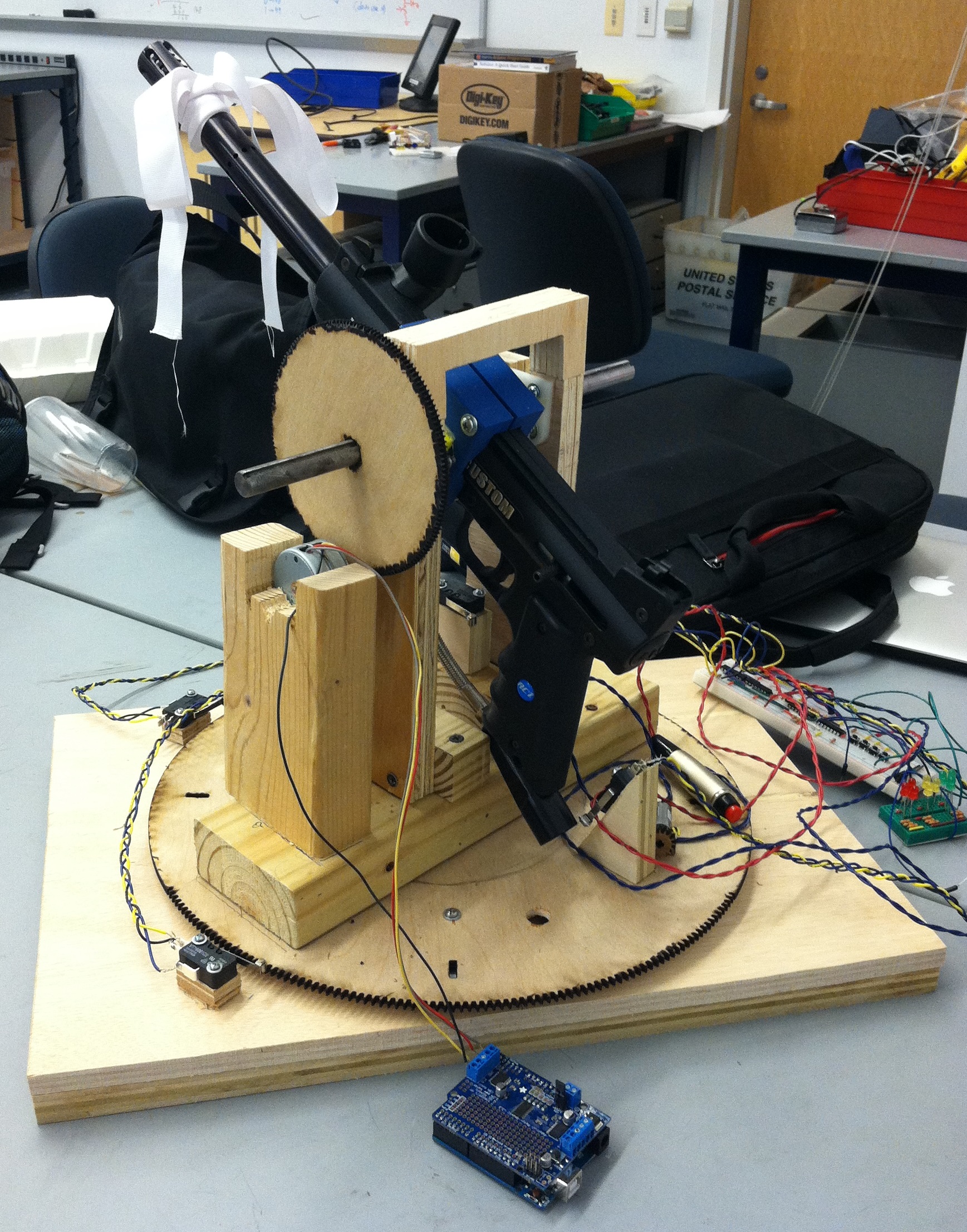

Our project began as it would end: with a series of bangs. We quickly acquired a Tippmann 98 Custom paintball marker, testing it to evaluate accuracy, adjust firing velocity, and determine basic system parameters. Based on these tests, we outlined a safety plan and came up with ideas for a final demo. We decided on a project organization scheme and got our Pivotal Tracker site and Github repository up and running. After calculating the marker’s moment of inertia and thus the motor torque required to move it, we ordered our stepper motors and developed initial plans for the pan/tilt gimbal mechanism. We then put our ideas into practice by constructing a gimbal prototype, designing a marker cage, and writing demos for foundational software concepts like motor control and computer vision.

Initial Partially-Integrated Prototype (November 7th, 2014)

In our second sprint, we acquired a turntable bearing and a webcam, setting ourselves up to begin work on software and mechanical design in earnest. We fabricated a marker mount and a pan surface from PLA and scrap wood, then designed a first iteration of the trigger mechanism. Using this partially-integrated prototype, we developed our electrical system design and made a fully functional set of safety kill switches to ensure we could control the entire system while testing. We also demonstrated PySerial stepper motor control (until our provisional wood gears stripped) and functional computer vision color detection with SimpleCV. Finally, we received the support of Olin’s designated safety personnel and the Babson campus police to move forward with testing and demonstrating our project.

Under-thought Exploratory Prototype (November 21st, 2014)

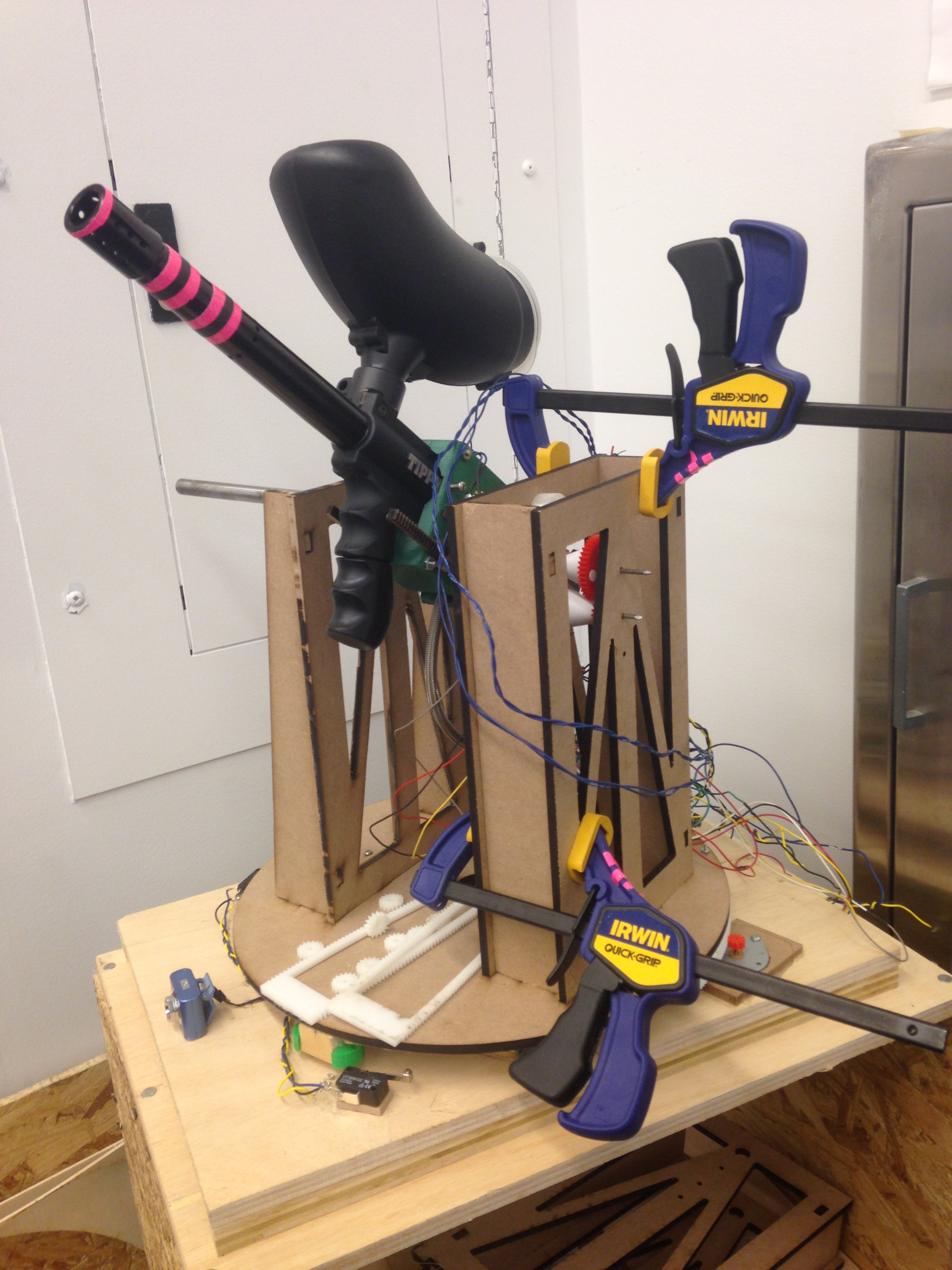

Our third sprint’s primary objective was to create a fully operational and testable prototype. Unfortunately, while we made good progress in several aspects of our mechanical design, we also encountered a series of setbacks due in part to poor design process. A decision was made (mostly through collective inertia) to fabricate new marker mount uprights from locally sourced scrap steel. The result was a non-structural, cobbled-together mess of a tower and several days of wasted machine shop time. We iterated the trigger mechanism another two times with two new motors, only to find that neither was strong enough to pull the trigger without a dangerous and cumbersome elastic assist. Had we done a little more thinking before iterating, we could’ve saved a lot of effort and moved forward faster. Though we made good progress on the pan motor mount and rack design in sprint three, our design review and sprint retrospective were moments of soul-searching. After renewing our commitment to some of our initial process decisions (like sub-teaming, Pivotal, and in-depth critical discussion of decision-making), we moved forward to sprint four with a completely new tower design and a return to our trigger mechanism’s roots.

Final Prototype (December 15th, 2014)

We began our final sprint by rapidly designing and constructing a new, sturdier pair of marker mount uprights from MDF. The new design incorporated a worm gear for tilting the marker - but after a day of playing around with the system, we decided to scrap the worm gear and instead craft a custom gearbox. During this redesign process, we also modified the pan surface to support the new marker mount. Instead of trying to make the trigger work by increasing mechanical complexity, we iterated our circuit design and reverted to a version of the original trigger mechanism. After testing, we revised this design slightly for increased durability and stability. After cleaning up our circuitry and making a few last-minute revisions to the code, we were ready to test out and present Project Pop Pop Pop!