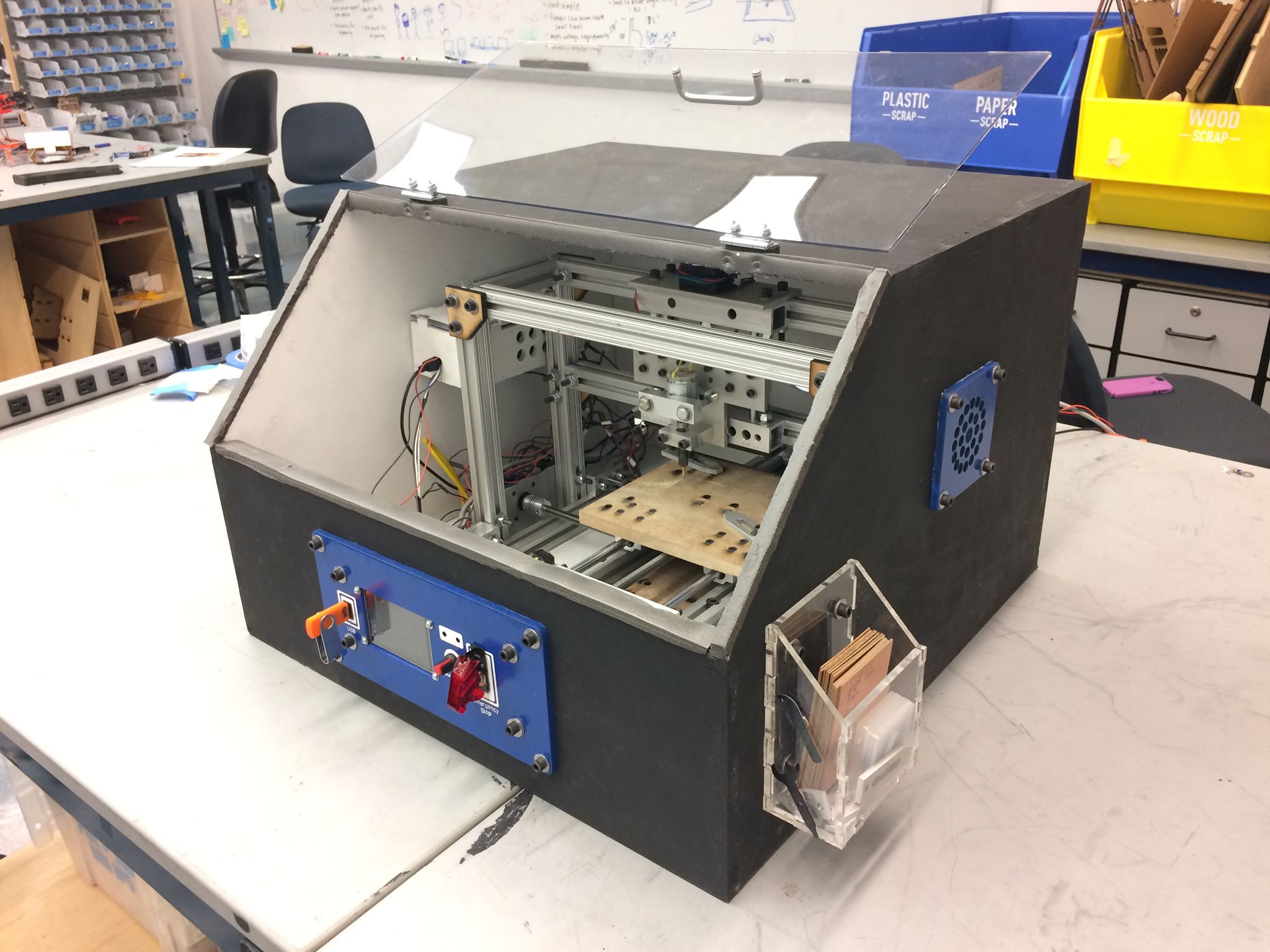

Enclosure

Final Design

The housing is made from ½” MDF and is designed to keep users safe from the cutting bit as well as dust and copper shavings. To achieve the latter, the housing includes a system of fans to cool the electronics and blow dust off of the platen.

Angled Viewing Window

A sheet of polycarbonate prevents fiberglass dust from leaving the enclosure and protects the user from tool failure. The angle allows for greater visibility while cutting to inspect the quality of the trace and for demonstration purposes. The window was lined with foam rubber to protect the polycarbonate and provide a seal when the door was closed.

Electrical Housing

A Small enclosures were designed to contain and protect the electrical components of our project. The first was located on the side of the box directly interfacing with the computer fan in order to regulate the temperature of the motor controllers. The second was located directly behind the front plate, holding the RasPi, knob for manual axis adjustment, USB extender, and emergency stop components.

Storage Case

An acrylic box serves as a convenient place to store cutting bits, PCB blanks, extra toe clamps, and information about how to use the machine. Additionally, it has magnets to hold the stock rotary tool wrench as well as the custom wrench allowing the chuck to be tightened without being in its original housing.