Specifications

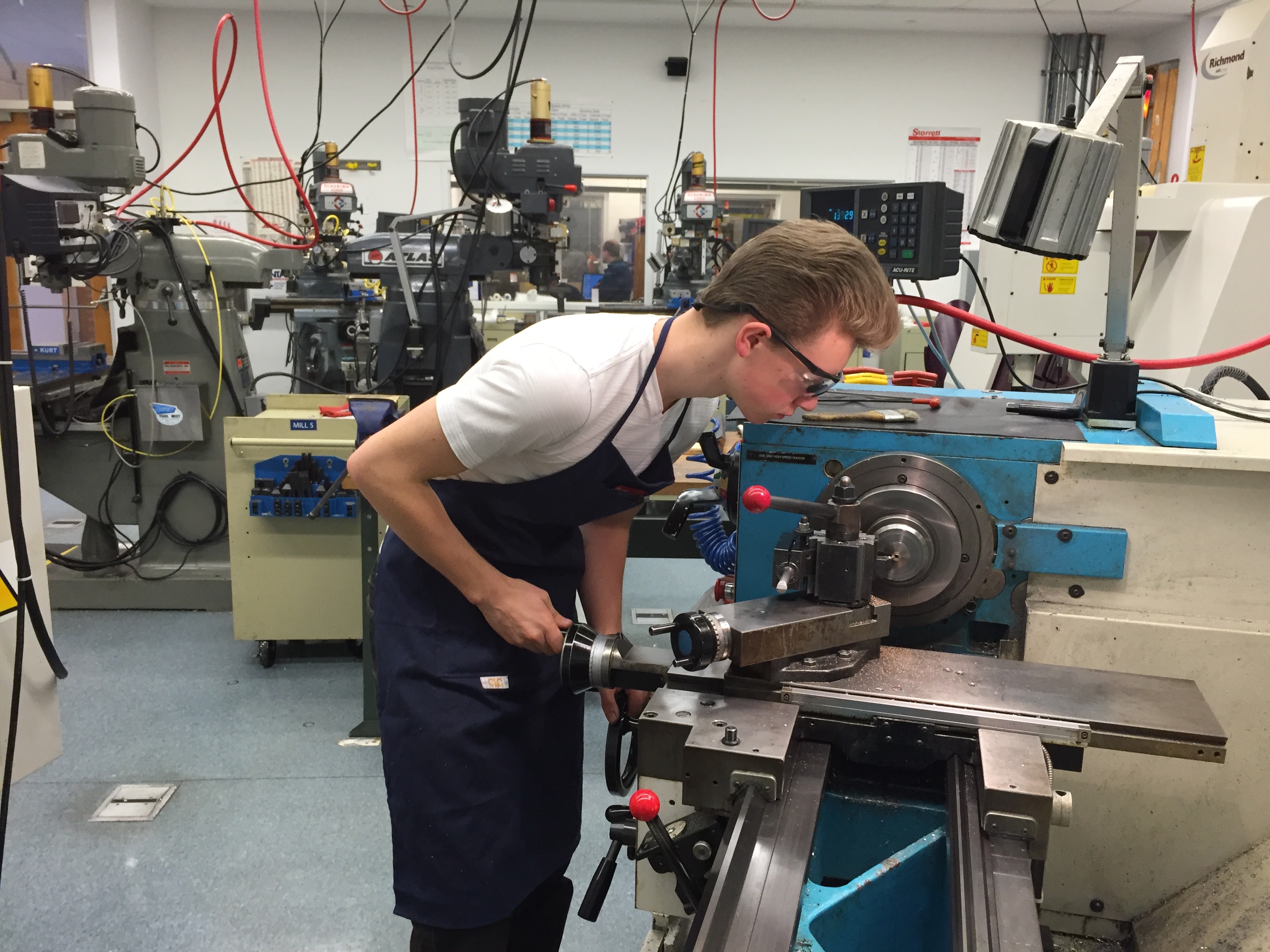

We designed and fabricated our mechanical system in-house

Mechanical Design

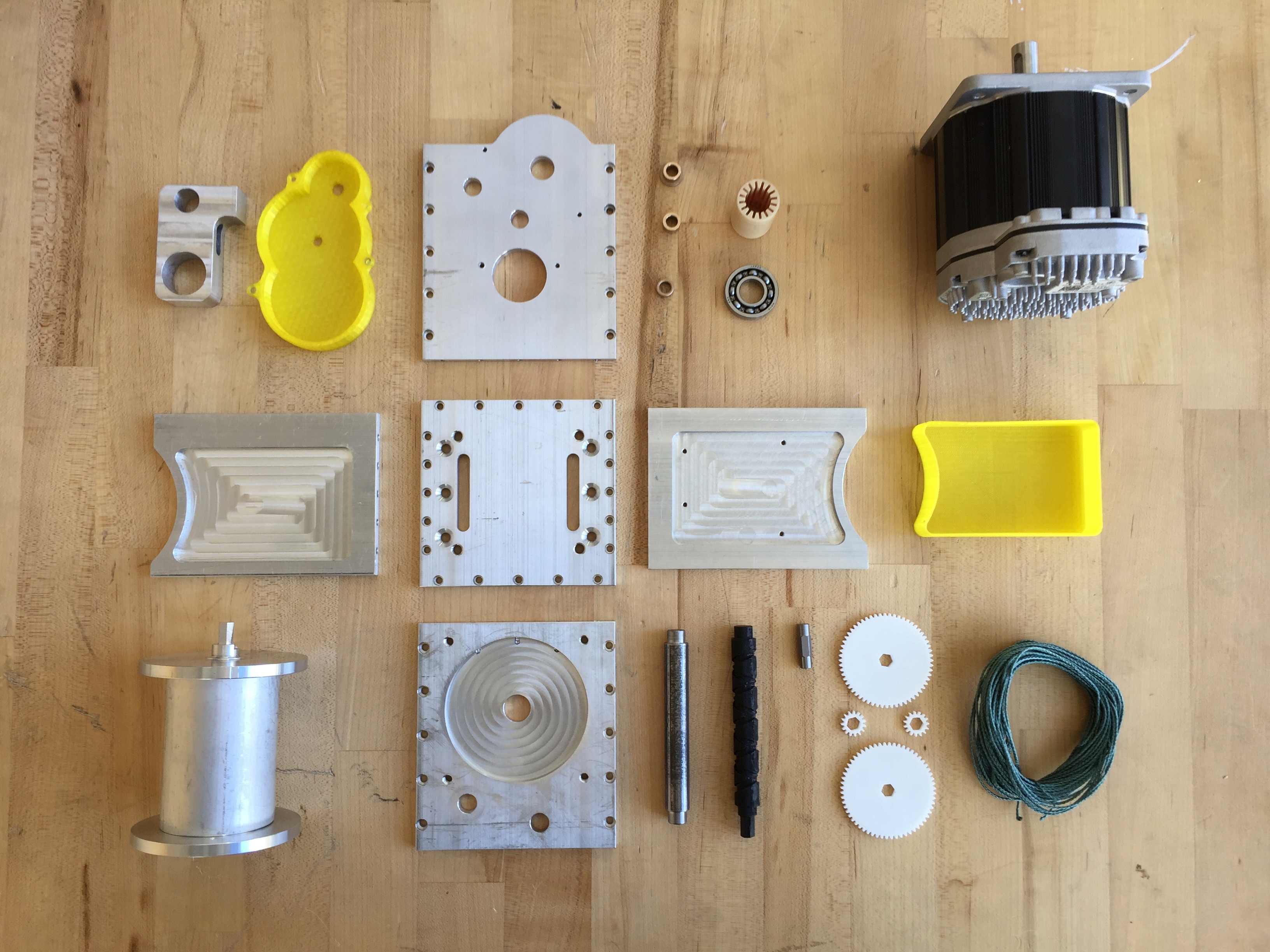

The mechanical component is three nodes capable of precise controlled spooling of a light, high strength wire dyneema cable. We followed an iterative process to reach the final mechanical version. We started by getting a simple 3D printed and quickly machined version to allow for testing of the software right away. From there we spent a good amount of time collaboratively designing in CAD to create a more refined version of the nodes. Once we were confident in our design we manufactured a complete node using 3D printing and machined plastic. This rapid manufacturing allowed us to quickly test to make sure everything worked how we were expecting before investing a huge amount of time and resources machining the final iteration.

After making changes based on our learning from the plastic version we made some changes and started manufacturing the final 3D node. These nodes are built from precision machine aircraft grade aluminum plates bolted together, integrating all the physical components into a clean and portable package. The biggest mechanical challenge involved was controlling the spooling of the wire so distance can be precisely controlled through revolutions of the motor. This was done with a self reversing screw driving a follower block, which guides the spooling cable and advances it precisely 1mm every revolution of the spool. This screw is specially designed to automatically reverse direction when it reaches the the end of spool allowing us to directly couple the screw to the rotation of the spool. Each node is mechanically identical containing 48 screws, and more than 20 custom made, unique parts.