Mechanical system

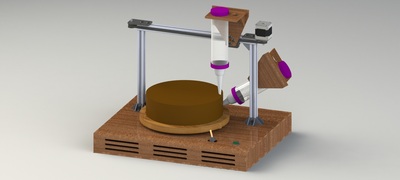

Our mechanical system must move a mechanism that pumps out frosting across the top of a cake to create designs. This system consists of three major components: the frosting dispenser, the gantry, and the rotating turntable.

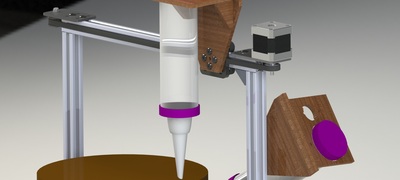

The frosting dispenser consists of a DC motor that has a gear system to turn a nut that moves a lead screw plunger to apply frosting to the cake. The Wilton Dessert Decorator Plus had a hand controlled plunger system that pushed frosting out in consistent, preset increments. We took out the original shaft and replaced it with a lead screw. This lead screw is driven by a nut that was press fit into a 3D printed gear, which was turned by another 3D printed gear that was press fit onto the shaft of a DC motor. The ratio between the motor gear and the nut gear is 1:2, which means that the motor can apply more torque to the lead screw nut, but it will move slower. The lead screw moves up and down because the nut that turns it is held in place so that it cannot move up and down and the plunger has enough friction with the barrel such that the lead screw does not turn. If either of these conditions is not met, the lead screw would not translate at all. We attached all of the parts in this system to a laser cut MDF holder that can be attached to a carriage which provides the motion along the radius. The MDF holder must be easily detached from the carriage so that we can easily refill the frosting. We are using the same frosting applicator for the side of the cake, but it is mounted at an angle rather than perfectly horizontal because it would be not be able to properly apply frosting in that orientation.

To move the frosting applicator back and forth over the top of the cake, we built a timing belt pulley system to move along the top of a frame built from 20 mm x 20 mm extruded aluminum. The timing belt pulley system has a Nema 17 stepper motor with a timing pulley attached to the shaft such that it can turn the timing belt. The timing belt pulley system moves a carriage that slides along the top of the extruded aluminum frame. Though we had intended to move the side frosting applicator, we were prohibited by time and budget. Thus, the side applicator is simply mounted on the extruded aluminum frame.

To create the circular motion necessary for our radial frosting application, we created a rotating platform for the cake*. The cake itself sits on a bamboo cutting board that we cut into a circular shape and engraved with a line to show exactly where the cake needs to go. This bamboo platform sits on a lazy Susan that is attached to it and the box that holds our entire system, keeping everything secure and allowing the platform to rotate easily. We attached the stepper motor that turns the platform with a universal mounting hub.

The frosting dispenser consists of a DC motor that has a gear system to turn a nut that moves a lead screw plunger to apply frosting to the cake. The Wilton Dessert Decorator Plus had a hand controlled plunger system that pushed frosting out in consistent, preset increments. We took out the original shaft and replaced it with a lead screw. This lead screw is driven by a nut that was press fit into a 3D printed gear, which was turned by another 3D printed gear that was press fit onto the shaft of a DC motor. The ratio between the motor gear and the nut gear is 1:2, which means that the motor can apply more torque to the lead screw nut, but it will move slower. The lead screw moves up and down because the nut that turns it is held in place so that it cannot move up and down and the plunger has enough friction with the barrel such that the lead screw does not turn. If either of these conditions is not met, the lead screw would not translate at all. We attached all of the parts in this system to a laser cut MDF holder that can be attached to a carriage which provides the motion along the radius. The MDF holder must be easily detached from the carriage so that we can easily refill the frosting. We are using the same frosting applicator for the side of the cake, but it is mounted at an angle rather than perfectly horizontal because it would be not be able to properly apply frosting in that orientation.

To move the frosting applicator back and forth over the top of the cake, we built a timing belt pulley system to move along the top of a frame built from 20 mm x 20 mm extruded aluminum. The timing belt pulley system has a Nema 17 stepper motor with a timing pulley attached to the shaft such that it can turn the timing belt. The timing belt pulley system moves a carriage that slides along the top of the extruded aluminum frame. Though we had intended to move the side frosting applicator, we were prohibited by time and budget. Thus, the side applicator is simply mounted on the extruded aluminum frame.

To create the circular motion necessary for our radial frosting application, we created a rotating platform for the cake*. The cake itself sits on a bamboo cutting board that we cut into a circular shape and engraved with a line to show exactly where the cake needs to go. This bamboo platform sits on a lazy Susan that is attached to it and the box that holds our entire system, keeping everything secure and allowing the platform to rotate easily. We attached the stepper motor that turns the platform with a universal mounting hub.