Components

Specs

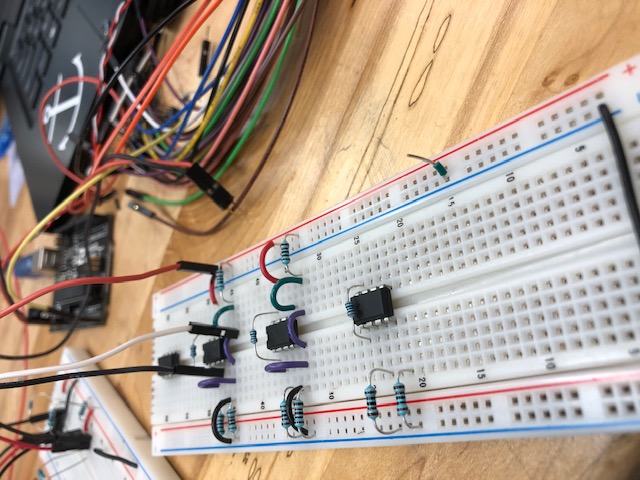

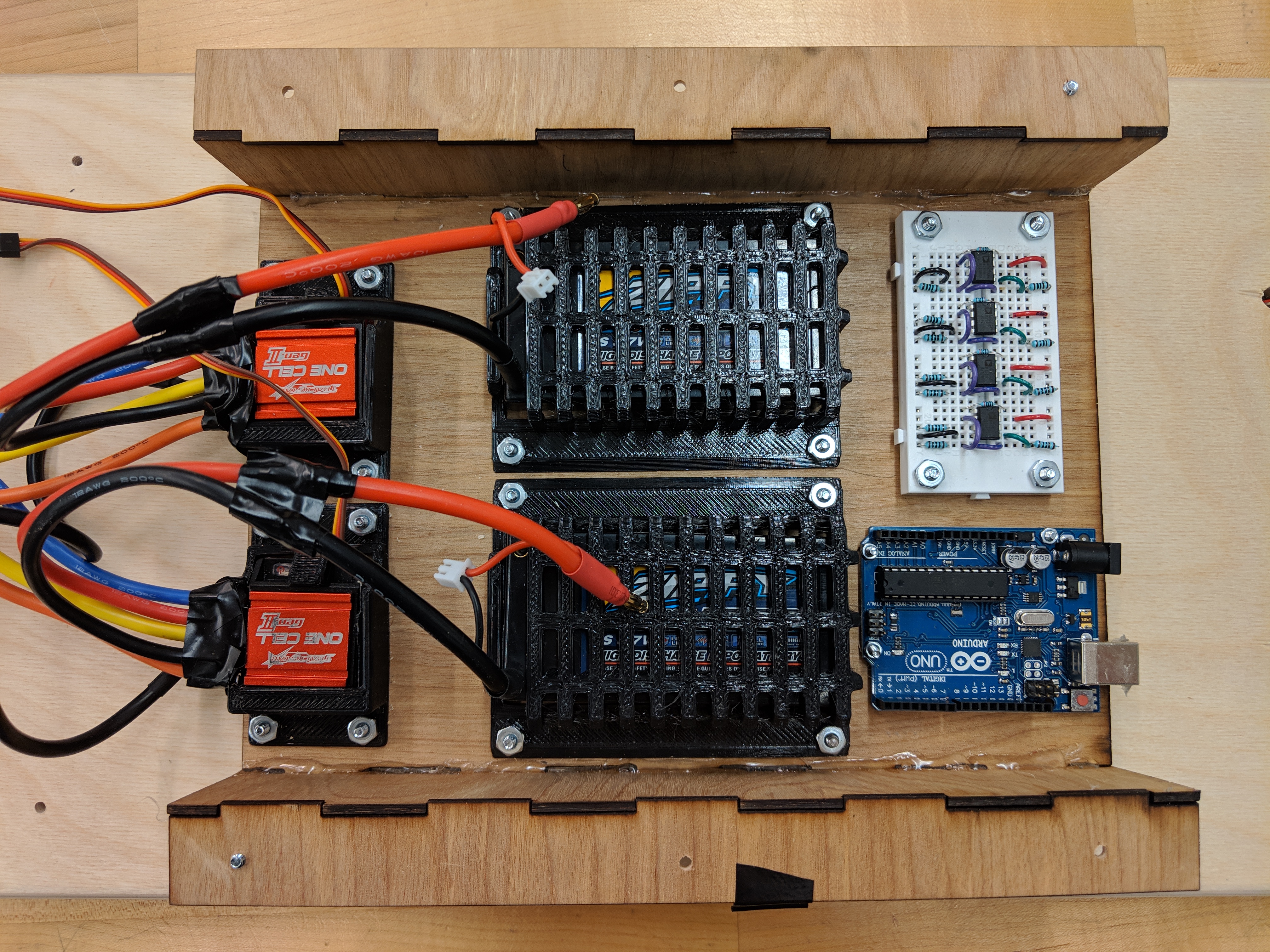

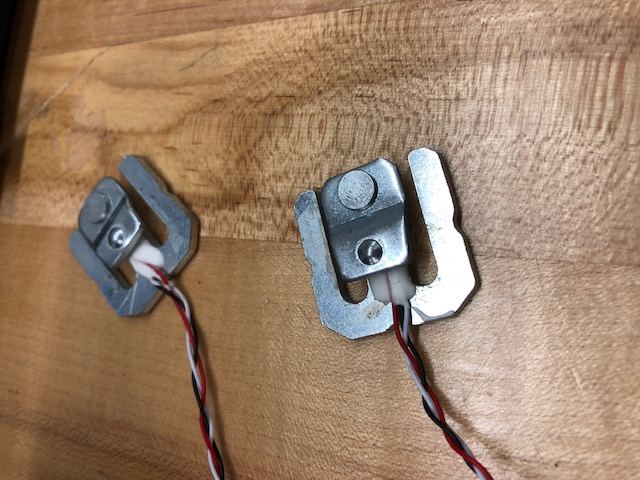

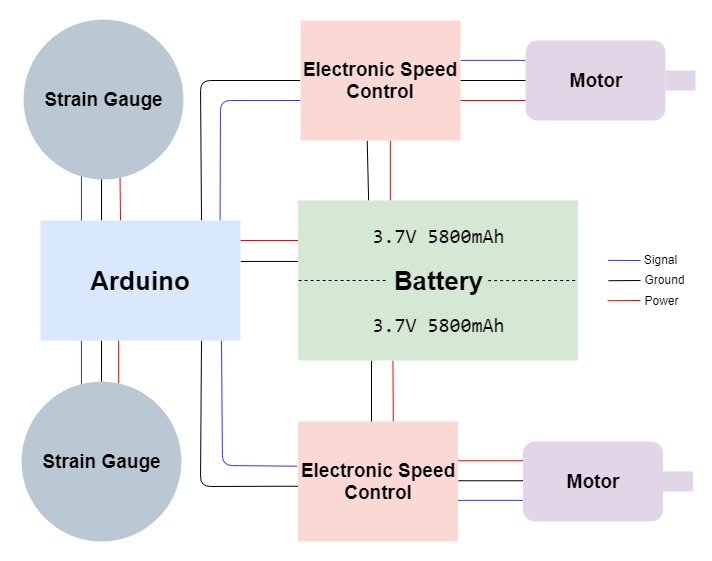

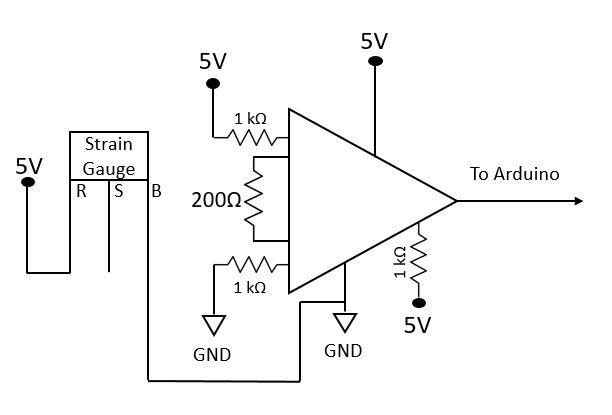

Our board is powered by two one-cell (3.7V), 5800mAh Lithium-polymer batteries; the power from these batteries is regulated and transferred to the motors using two Turnigy Trackstar One-Cell Electronic Speed Controllers (ESC). The brushless DC motors used in conjunction with the ESCs are also from the Turnigy Trackstar One-Cell line, with these specific ones operating between 80A and 120A, with a KV value of 6580. We used a standard radio receiver and controller for the RC stage, and the strain gauges for the pressure stage were taken directly from a bathroom scale. The brains of the board are controlled by an Arduino Uno microcontroller.