Mechanical

We started this project with the goal of using rapid prototyping technologies as much as possible. For our earliest prototypes, this meant prototyping with cardboard and hot glue. After validating our initial designs, we quickly turned to laser cutting and 3D printing. These became our go-to methods of fabrication. We found that ¼” plywood has the perfect balance of rigidity and cost effectiveness. For non-planar parts, we used Olin’s Makerbots. This approach allowed us to quickly evaluate and iterate on prototypes.

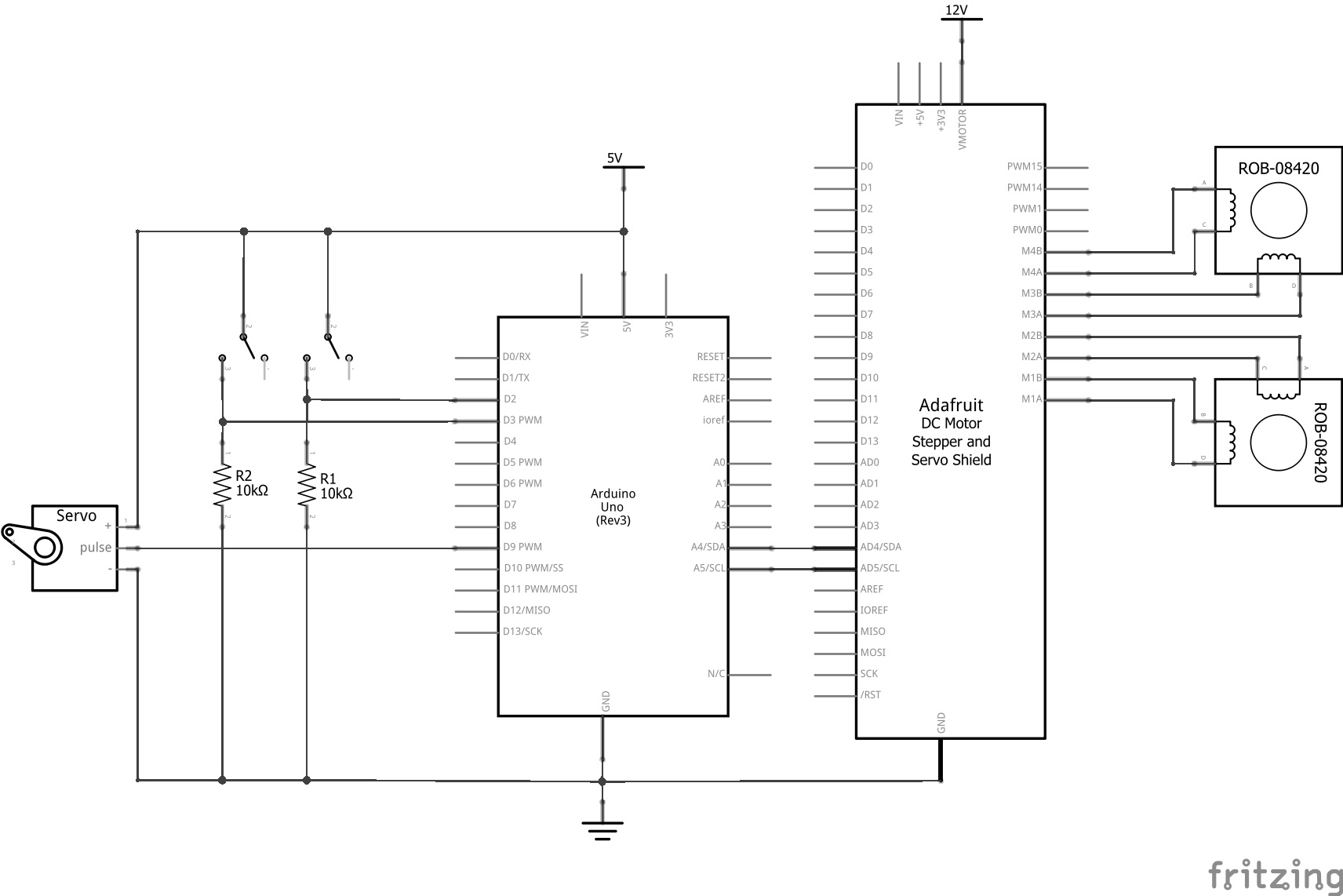

The machine’s most important axis is also the simplest. Our egg rotation system is made up of only five parts. We are using two custom 3D printed “holders” that clamps the egg in place. The top holder is spring loaded, and has a bearing to keep it concentric. The bottom holder is press fit onto a stepper motor. We experimented with o-rings and rubber bands to add friction between the egg’s surface and our 3D printed parts, but found that a ring of hot glue actually works best to keep the egg aligned.

The egg decorator’s vertical axis is its most precise axis of movement. We used an off-the-shelf lead screw kit that couples directly to our second stepper motor. We then designed a guide system using inexpensive carbon steel rods and low-friction linear bearings. The 3D printed base component for vertical motion also acts as a brace that aligns all of our structural elements.

The egg decorator also has a plunge axis, which is capable of pushing a pen or engraver into the egg. This allows us to draw discontinuous shapes (like a smiley face). This system is powered by a standard hobby servo motor in conjunction with a custom rack gear and spring for error compensation. This entire subsystem was designed to be modular - this makes changing pen tips easy, and leaves the door open for other decorating procedures, like carving.