Goals and Focuses

- Finalize installment location

- Finish attachment structures

- Add more complexity to the system

- Create polished gears, pulleys, and backboards

- Integration of all mechanical and electrical components

- Solve internet connection issue

- Add a Twitter API for more variety

Achievements and Processes

We met with facilities to finalize our installation location.

Our final meeting with facilities gave us the exact location where we would install Kinnect, which is in the hallway next to the mailing room. The location has a lot of daily traffic and thus provides enough attention to Kinnect. On the other hand, since our installation would be hanging on the wall, we would not obstruct the traffic. However, because there is no ethernet connection within reachable distance, we decided to use a WiFi shield for our Raspberry Pi.

Our final meeting with facilities gave us the exact location where we would install Kinnect, which is in the hallway next to the mailing room. The location has a lot of daily traffic and thus provides enough attention to Kinnect. On the other hand, since our installation would be hanging on the wall, we would not obstruct the traffic. However, because there is no ethernet connection within reachable distance, we decided to use a WiFi shield for our Raspberry Pi.

We made a French cleat mounting system to secure the sculpture onto the wall.

We decided to use a French cleat mounting system, because it is minimally intrusive and also easily and quickly attachable and removable.

We decided to use a French cleat mounting system, because it is minimally intrusive and also easily and quickly attachable and removable.

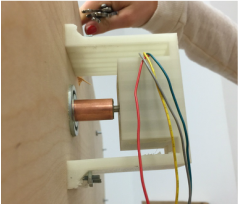

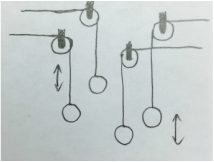

Added extra movement to the system for aesthetics

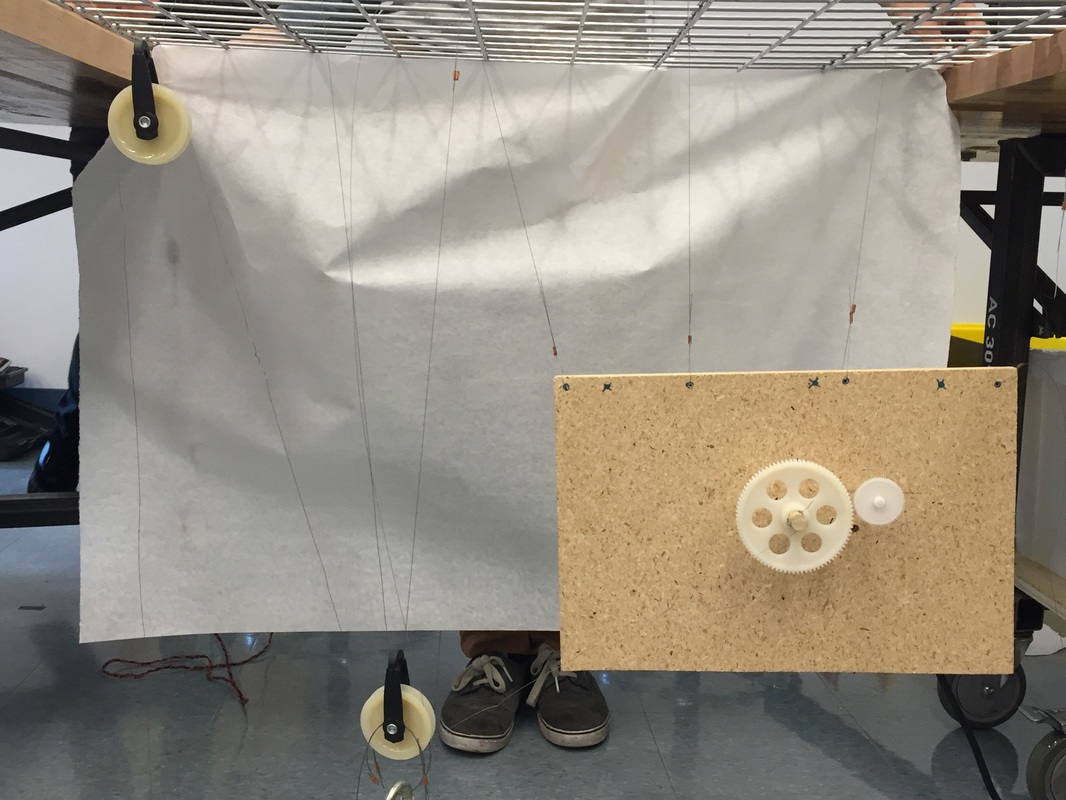

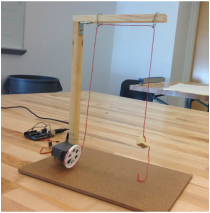

We added another gear as shown below to give the sculpture a more complete look. We also increased the size of the gears and pulleys to occupate the board better.

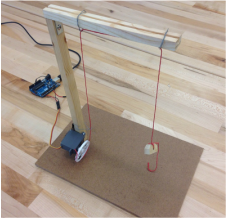

We made new, polished, and sturdier gears, pulleys, and back board.

To achieve a more sophisticated look for Kinnect, we decided to use wood stain, gloss, and paint to give our sculpture a new look. We also laser cut new gears and pulleys with thicker woods for a sturdy look and durability. The backboard was painted white to match the wall for installation. All components are assembled with the new and more polished materials.

To achieve a more sophisticated look for Kinnect, we decided to use wood stain, gloss, and paint to give our sculpture a new look. We also laser cut new gears and pulleys with thicker woods for a sturdy look and durability. The backboard was painted white to match the wall for installation. All components are assembled with the new and more polished materials.

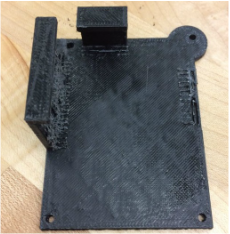

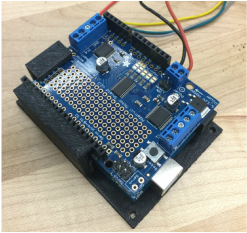

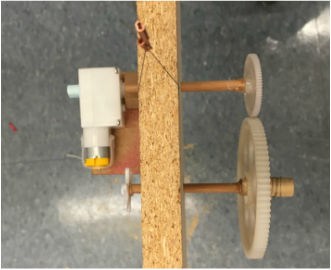

We integrated the electrical components with the back board.

To achieve so, we became friends with the 3-D printers! With some adjustment to the printed product, the harnesses fit like a glove. 👐

To achieve so, we became friends with the 3-D printers! With some adjustment to the printed product, the harnesses fit like a glove. 👐

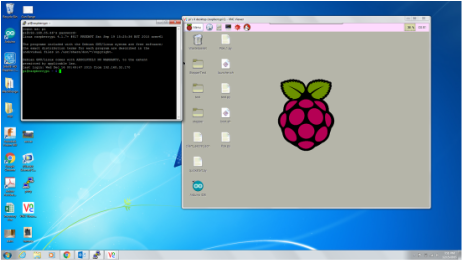

WiFi connection for the Raspberry Pi...an early Christmas present

Since there is no ethernet port near our installation site, we had to purchase a WiFi dongle for our Raspberry Pi. It magically arrived on time, just like an early Christmas present. And, pleasantly, it worked quickly.

Future Risks

In general, we are very proud of our project. 👪

However, this is not to say that our project will function in eternity like we would love to see (but can we live that long to see eternity?) If we had more time, we would try to make the system fully independent and automatic. We realized that if the power source of the system is cut off, we would have to use VNC to restart the system in Raspberry Pi. This is not ideal because we would have to constantly check the sculpture for its functionality, especially because it is at a location of high traffic, and people may trip over the wire.

In general, we are very proud of our project. 👪

However, this is not to say that our project will function in eternity like we would love to see (but can we live that long to see eternity?) If we had more time, we would try to make the system fully independent and automatic. We realized that if the power source of the system is cut off, we would have to use VNC to restart the system in Raspberry Pi. This is not ideal because we would have to constantly check the sculpture for its functionality, especially because it is at a location of high traffic, and people may trip over the wire.

RSS Feed

RSS Feed