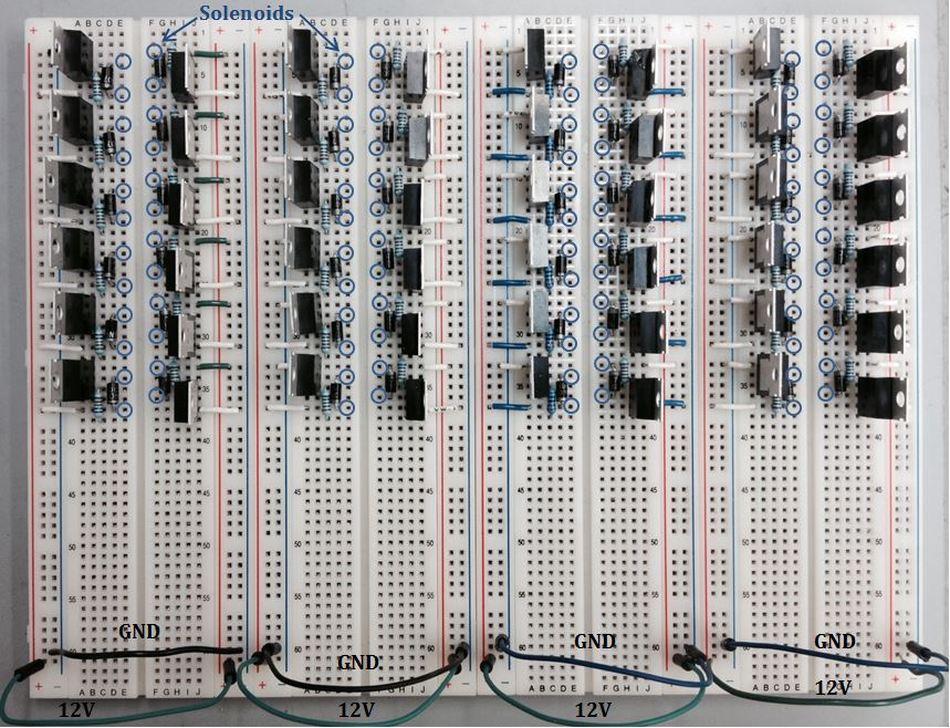

To create the six pins of each Braille character, we coiled our own solenoids to save our budget and potentially create smaller solenoids than we could buy easily. We built a circuit that used TIP120 transistors and IN4007 diodes to keep the solenoids from drawing power from the Arduino Mega. Instead, we attached a 12V power supply to generate the current for our solenoids. Our converter would display a total of eight Braille characters at a time, and refreshed the characters when a button was pressed.

Solenoids

Our project demanded a very large amount of actuators and with even the most basic solenoids costing nearly $5, we decided to investigate winding our own solenoids. Commercial solenoids require hundreds if not thousands of turns to deliver a sufficient linear force as well as carefully designed thermals to prevent overheating due to high current draw. In our design, each solenoid was only active for 250 ms at a time and only needed to deliver enough force to lift its metal actuator (which was a piece of music wire). As a result, we concluded that we would be better off manufacturing our own solenoids. Each solenoid averaged 2W when attached to a 5V rail.

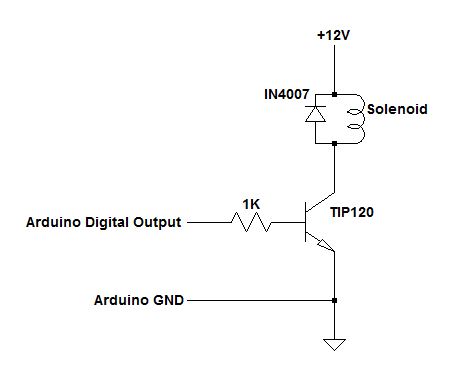

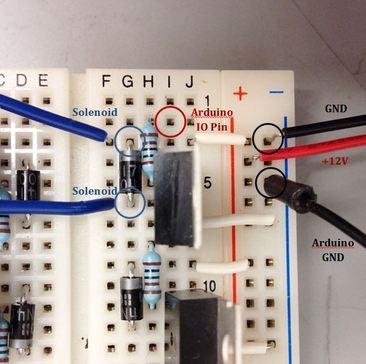

Solenoid driver

Because the Arduino Mega microcontroller could not provide the current necessary to power our solenoids, we referenced and constructed a simple solenoid driver circuit. This circuit utilized a Darlington transistor (admittedly overkill) to switch a maximum of 3A by having the Arduino Mega’s digital pins control the base.

Control

Before settling on the Arduino Mega, we investigated several ways of controlling a large number of actuators. First, we considered using the Arduino Uno to control a chain of shift registers. This design was considered first because we originally aimed for maximum extensibility. However, we scaled back our desired number of pins and it became more practical to use the Arduino Mega, where each solenoid could be controlled by an individual digital IO pin.

Power

Large numbers of actuators have the potential to draw outrageous amounts of power, even if just for an instant. We found from electrical testing that our solenoids drew about 600mA each. While the power supplies provided in the PoE lab were sufficient for the number of solenoids present in our sprint reviews, their maximum current delivery of 5A would not be enough to power the highest possible demand from 8 characters worth of 6 solenoids each, our desired character count. The lab power supply was replaced by a computer supply that could deliver up to 15A from its 5V rail. Although this would also not be able to meet the demand of 48 solenoids firing instantaneously, no braille character requires more than 5 pins to fire at once, the most common consonants, RSTLN, require no more than 4, and all vowels require no more than 3.

solenoid-driving Circuit

Single Solenoid Circuit:

Full SOLENOID CIRCUIT (8 Characters):

What went wrong

The original solenoids we manufactured for the sprint deliverables used 30 AWG wire and had a resistance of 8 ohms on average. When connected to our driver circuit, they would pull about 600mA each. Finding that these would heat up quickly and destroy their insulating enamel, we decided to go to a thicker gauge wire for our full scale manufacturing process. This turned out to be a critical mistake because in changing the wire gauge, we did not fully realize how the thicker wire would affect our solenoid performance. A 30 AWG wire has about 63% of the cross sectional area and 125% the coil density (turns per length) of the 28 AWG wire, which also implies that the complete coil, if straightened, would be longer. As a result, our 28 AWG magnet wire solenoids have less as much as 1/2 or as little as 1/3 the resistance of the 30 AWG wires. Their lower resistance causes them to demand a much higher current than expected. Because our power supply was barely enough for the original solenoids, there is no way that enough current can be sourced for the new solenoids. Additionally, the heat issue is even worse as the new solenoids are actually smaller, enclosed in a small box and don't have proportionally better thermals than the old ones.

Lesson learned: Follow through completely with the math.

Lesson learned: Follow through completely with the math.