return home

continuous updates, little frustrations, and major breakthroughs as we progress through this journey to discovery.

the final frontier

and so, team pinc comes to a close. check out our final product here.

sir.inge

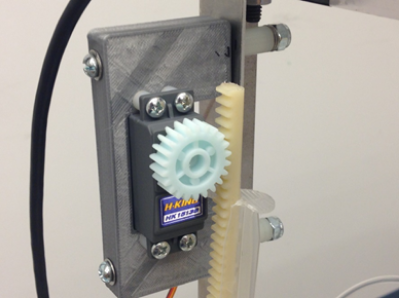

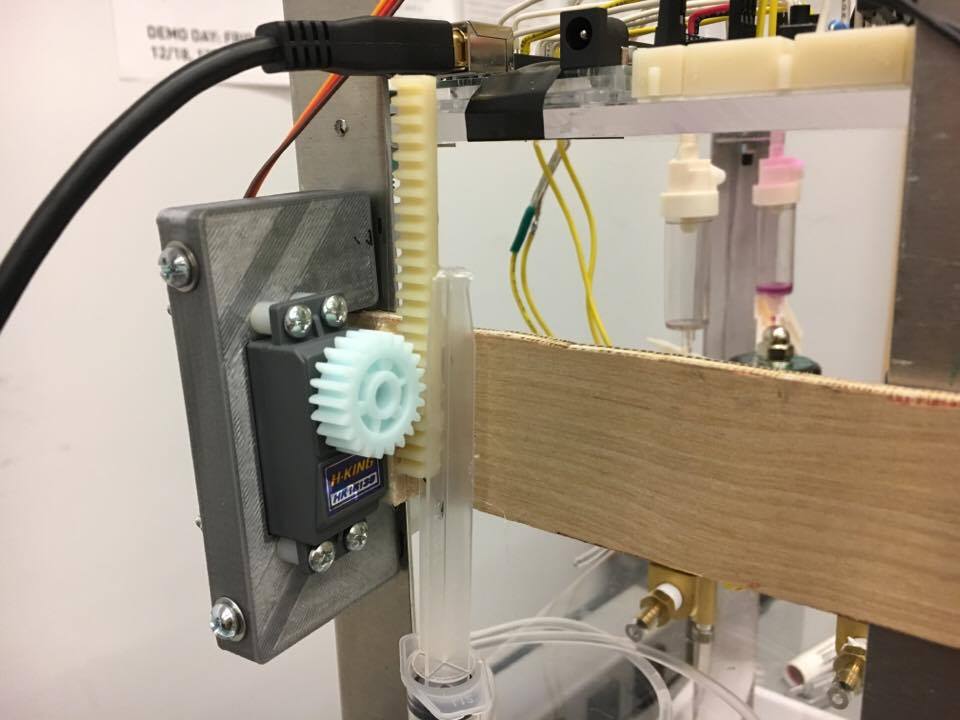

we've exhausted a couple of options in handling the syringe, which is vital to our ink dispensing and ink flushing system. our first attempt included the servo motor, a 3D-printed gear, and a plastic rack gear, where we'd use the gear glued onto the motor to translate rotational motion into linear motion to pump the syringe in the vertical axis.

this mechanism was trashed because the rack and syringe plunger would prefer to bend away from the pinon rather than be pulled up or down by it. we tried multiple solutions to constrain it but they all proved to be bulky and ineffective. we wanted to have only one degree of freedom -- up and down – but we were having trouble converting rotational motion into linear motion.

after some brainstorming, talking to NINJAs and prototyping, which included the birth and death of more ideas, we tried using a screw and nut. we grabbed another syringe, bandsawed the tip off so we could wedge the nut inside the bottom of it, and used it as a sort of tube to hold the screw and nut. we got a 12V DC motor to turn the screw, and because it and the syringe are fixed in place, only the nut and syringe plunger can move. this system showed promise because it did not slip out of place, but it suffered from not being able to pull the syringe up as far, and sometimes the motor would stall when trying to push fluid out.

we created a new mounting system that allowed more travel distance, coated the screw and nut in dry chin grease to solve these problems. while the system does not work as smoothly as we would like, we would probably need a bigger motor for that, it does work much better than any of our previous solutions.

sprint review pt. III

our last sprint review for the past two weeks. after this, we're gearing up to power through the last week of this project!

before turkey break...

it's that time for giving thanks, and we are feeling grateful for seeing more development on our pen. we are in the midst of putting together our multi-valve system, and we have our syringe, which is vital to our ink-dispensing as well as ink-flushing system, connected to a servo motor so that we can also easily control it with an Arduino.

most of our code is ready and waiting to be tested and calibrated once the mechanical prototype is fully completed. and we are fine-tuning our electrical wiring and components in addition. can't wait to come back from break and crank out the final sprint!

sprint review pt. II

another recap of the past two weeks, along with more progress videos!

briefly merging our worlds

within our beautiful castle of metal and acrylic, we've finally housed the beginning prototypes of our mechanical and electrical systems. cluttered by too many wires, too much plastic tubing, and a couple medical supplies (ie: syringes and IV drips), it's messy but it's home.

as of right now, we can control one valve system. what this means is that we have one plastic cup with one color of ink, or for purposes of current testing, water. with arduino input, we can open the solenoid valve connected to this container to let the ink flow through one IV drip. it goes through the syringe, which we still have to physically push ourselves, and out through the tip of the pen. then we can close the valve with the arduino on command. knowing that this runs pretty smoothly, it won't be too difficult to put together the rest of the system.

team pinc goes medical

iv drips are where it's at. from our last sprint, a major question that popped up was how are we going to control how much ink is flowing out from the reservoirs at any given point in time? how do we keep consistency? and iv drips are the answer. they have a standard flow rate, and they are easy to control. win win.

to continue with our theme, we also decided to implement a syringe as the foundation for our ink dispensing mechanism. we needed an airtight container so that the ink wouldn't just spill out, yet at the same time we needed something that could force out the ink when we needed it to. cue the syringe. we just need to determine how to mechanically control its plunger from an arduino input!

sprint review pt. I

it's important to reflect in order to move forward through this project effectively and efficiently. here's a summary of the past two weeks: what we wanted to learn, what we did learn, and some videos of our progress.

checking out the competition

we needed to understand which type of pen with which types of ink we wanted to model our system after. after studying the different pens -- ballpoint, roller-ball, fountain -- we found that fountain is the best because it uses water-based ink, which is easier to flush out.

when our fountain pen came in, we deconstructed it immediately and looked at how the ink behaved. it was pretty viscous, and it had trouble flowing smoothly through the plastic tubing we bought. surface tension in the pen depends on the diameter of the tube and the properties of the ink, and since we couldn't change the tube diameter, we tried adding detergent to the ink to affect its behavior. this helped the ink flow so much better.

we can sense the rainbow

shoutout to Drew for the nice color sensor. much more accurate and consistent, we've been able to avoid some obstacles like funky, unexpected outputs for specific colors, and so push forward with the calibration of the color sensor. now, we also integrated the color sensor with MATLAB so that we can project user feedback on the screen, the feedback being whatever color is being sensed. it's still a work in progress, since the color output isn't quite accurate yet, but we plan on cranking through much more calibration to improve this. we also did some lasercutting to construct a "black-box" container for this sensor.

many, many firsts

we crossed a lot off of our to-do list.

we had to do some running around to scavenge some components from various stockrooms and labs around campus. We ran a first draft of the circuit on a breadboard, with 1024 as the output for white light input and 150 as the output for a finger blocking light input. Then we moved on to create a condensed version of this on a perf board, soldering resistors and LEDS right and left.

then we iterated, Sean 3D-printing a "black-box" cylinder and wiring the three color LEDS together with the photodiode. After connecting it to an Arduino and testing it with white light versus colors from random objects in the lab, we ran into our first problem with the outputs for green. Drew, one of our advising professors, came over with a TCS3200 color sensor, so that may be our next iteration.

mechanically, we were inspired by titration in chemistry to control ink flow. so, for our first order, we bought a solenoid valve (so that we can easily control the valve with an Arduino), a barb adapter, a fountain pen for research, and plastic tubing.

kick it off with a killer preproposal

cheers to team pinc! our first task to conquer was to meet together and converge on what we were all imagining when we heard the phrase "color-sensing pen." we compiled resources for inspiration, predicted possible obstacles, and established what our MVP would look like. check out our preproposal below: