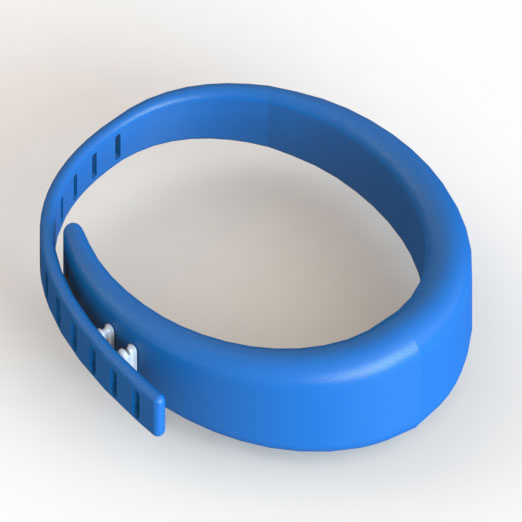

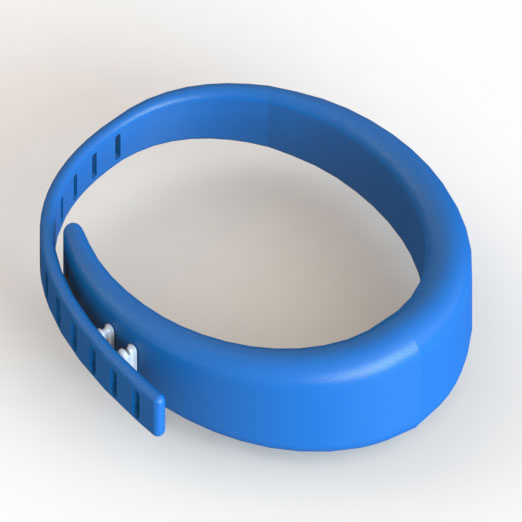

It starts with design

LeadMe is designed to fit comfortably around any ankle, while protecting the electronics inside.

Get to the places that matter most

without the distractions

LeadMe is designed to be simple and beautiful. The electronics are cast directly into a silicone casing, so durability and water resistance are built in.

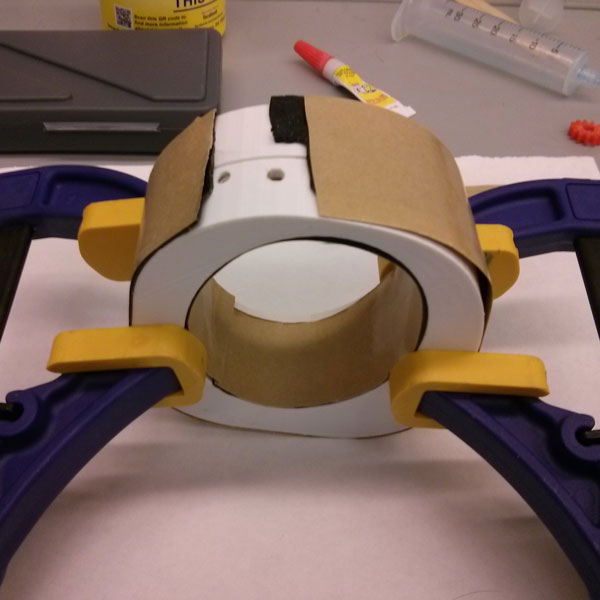

After 3D printing and carefully finishing a mold, the electronics are placed inside and flexible yet resilient silicone is added around it. Once the silicone has cured, the budding anklet is placed into a second, larger mold, and another layer of silicone is added around it to ensure the electronics aren't near the surface.

LeadMe exists to stay out of the way. With a slim, durable form factor, LeadMe means you just get there.

LeadMe is designed to fit comfortably around any ankle, while protecting the electronics inside.

A 3D printed mold, finished with epoxy, is filled with silicone and allowed to cure for about 12 hours. The electronics are embedded directly into the silicone.

Once the silicone is cured, the mold is carefully removed and LeadMe is ready to be used.

LeadMe's mechanical design is deceptively simply, requiring few components:

For technical details, click here.